The 20 most expensive buildings in the world: from super mosques to luxury casinos

3D printing technology is heralding a revolution in the construction industry: buildings that are currently still being constructed through labor-intensive craftsmanship could in future be grown layer by layer from a printer. The costly dream of owning your own home thus becomes a calculable and customizable project. Ambitious construction projects – such as the first earthquake-proof villa from a 3D printer in China – have been causing a stir for years and provide insights into the architecture of tomorrow.

While materials such as concrete, metal, and plastic have been used primarily up to now, a renewable material is increasingly coming into focus: wood. 3D printing with this natural material opens up completely new possibilities for sustainable construction – a development that can have a positive impact on both the architecture sector and the environment.

3D printing with wood for sustainable construction

3D printing with natural materials such as wood still requires extensive research and development, particularly regarding load-bearing capacity and material durability. However, the progress made so far is promising: if the ecological advantages of wood can be combined with the efficiency of additive manufacturing, 3D printing with wood will open up completely new avenues for the construction industry.

Customization and design freedom, easy reproducibility, cost efficiency, and environmental friendliness are among the compelling arguments in favor of this technology. The use of materials is also extremely resource-efficient – in 3D printing with wood, only the amount actually needed is processed, which virtually eliminates waste.

Wood also offers excellent thermal insulation, making it particularly energy efficient. This renewable raw material, with its long service life and flexibility, is therefore particularly interesting for sustainable construction projects. Projects involving building with bamboo or wood show how natural materials and modern technologies can be combined in a meaningful way – an approach that is also likely to shape 3D wood printing in the long term.

Research and development: From Laywoo‑D3 to pure wood

Additive manufacturing with natural materials is a dynamic field of research – especially regarding strength, dimensional stability, and material purity. 3D printing with wood is at the forefront of this field, as the material is ecologically sound and surprisingly versatile in terms of formability. The aim is to be able to produce both delicate and load-bearing elements with the highest possible proportion of renewable raw materials.

“Laywoo D3” – a wood filament from the 3D printer

Research into wood in 3D printing is primarily focused on interior design, furniture, and building components. The first promising projects are already underway: engineer Kai Parthy has developed the wood filament “Laywoo-D3.” It contains 15 to 40 percent recycled wood by weight. Visually, the filament is almost indistinguishable from real wood. It even has the characteristic smell. It can be printed at temperatures between 175 and 250 degrees Celsius. The temperature determines the color – the more heat is applied during the printing process, the darker the result. This means that growth rings, among other things, can be imitated in 3D printing with a wood look.

The further development of Laywoo-Flex has given the Laywoo-D3 wood filament additional flexibility: the 3D-printable filament has the flexibility of fresh branches, yet without the artificial impression of a rubbery material. This expands the range of applications for 3D printing with wood to include flexible applications, such as furniture design or functional prototypes. Despite these promising approaches, there is still a long way to go in terms of research before it is possible to print wood in its pure form.

Ongoing research

Researchers around the world are continuing to advance 3D printing with wood – particularly in the area of adaptive, bio-based, and material-intelligent applications. In addition to optimizing the filament, the focus is also on new functional principles and natural reinforcement processes.

> MIT – hygroscopically active composites: The Self-Assembly Lab at the Massachusetts Institute of Technology (MIT) is experimenting with 3D-printed wood-PLA structures that deform automatically in response to changes in humidity (4D printing). The programmed panels exhibit controlled curvature or folding – without motors or electricity, but rather solely through passive influences. Such materials could react dynamically to climatic conditions; for example, for adaptive façades or modular interior designs.

> IAM – Mycelium meets wood: In projects such as “MyCera” by the Institute of Architecture and Media (IAM) at Graz University of Technology, 3D-printed wood-clay foam is combined with fungal mycelium. The mycelium actively grows into the structure, binding individual components and naturally solidifying the entire system. The aim is to create new materials that are biodegradable, dimensionally stable, and load bearing.

> IHD Dresden – Wood content up to 90 percent: The Institute for Wood Technology in Dresden is developing filaments with a high wood content of up to 90 percent that almost completely dispense with fossil polymers. A combination of the finest wood flour and biodegradable carrier material is used, processed using the fused filament fabrication (FFF) process. The aim is to achieve 3D wood printing that comes as close as possible to the raw material wood, both ecologically and in terms of its material effect.

These projects show that wood is no longer a niche material in 3D printing. It is becoming intelligent, responsive, and biologically active. This expands its range of applications beyond pure shaping to include sustainable, adaptive materials that adjust to their environment.

Fields of application: Interior design, design, and biostructures

3D printing with wood is already being used in its first practical applications – primarily in design, furniture construction, and interior design. Wood-PLA filaments enable detailed, aesthetically appealing objects with a genuine wood structure.

> Interior design & furniture: Numerous designers use 3D wood printing to produce custom-made connectors, modular furniture parts, or decorative elements. 3D-printed PLA connectors join wood panels securely and stably – an approach that has proven itself in prototype construction and small-batch production.

> Decoration: Prototypes such as vases, bowls, and room dividers are created from a combination of 3D-printed wood clay and fungal mycelium. These biologically reinforced objects are dimensionally stable, fully compostable, and an example of how organic materials can be used functionally through additive manufacturing.

These real-world applications clearly demonstrate the creative and functional potential of 3D printing with wood today. It opens up new avenues in areas such as design, prototyping, and bio-based product development – sustainably, flexibly, and with added creative value.

Comparison: Wood, carbon, and other materials

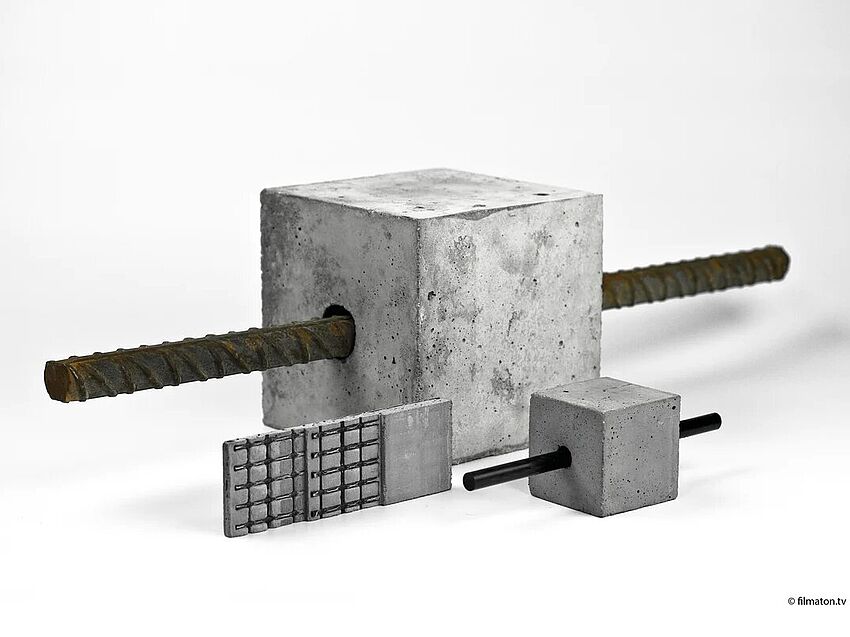

3D printing with wood complements a growing range of materials in digital construction. While natural materials are particularly appealing in terms of sustainability, technological innovations such as carbon concrete open up new possibilities for particularly high-performance structures. Wood is positioning itself as an ecological alternative – flexible, renewable, and versatile in design.

Carbon in 3D printing: Lightweight, stable, high-performance

Carbon concrete is becoming increasingly important as a material for additive processes in the construction industry. A remarkable example is the resource-saving jet process developed by the University of Augsburg. This involves incorporating short carbon fibers into cementitious building materials, which gives the material – FIBRACRETE – enormous strength. Carbon fibers can withstand high loads and are around 80 percent lighter than steel. The foundation stone of the new “Materials Resource Management” (MRM) research building in Augsburg has already been laid using FIBRACRETE – printed with 3D technology.

Wood in comparison: natural, versatile, resource-efficient

Compared to carbon, wood is particularly impressive in 3D printing from an ecological perspective: it is renewable, stores CO₂, is recyclable, and is significantly more energy-efficient to process. With its natural texture and warm appearance, wood also offers design advantages, especially in interior design and architectural details.

Although wood filament does not achieve the strength of carbon fiber, it is a resource-saving alternative in non-load-bearing areas. Wood really comes into its own in 3D printing when it comes to individual design solutions, surfaces, and modular elements.

Outlook: Where is 3D printing with wood headed?

In the coming years, 3D printing with wood will increasingly evolve from decorative niche applications to functional solutions in the design and construction sectors. In the fields of interior design, furniture design, and customized small series production, the process offers great potential thanks to its design versatility, sustainability, and ease of post-processing.

As material quality improves, new areas of application are also coming into focus. Filaments with up to 90 percent wood content – such as those currently being tested at IHD Dresden – could bridge the gap between design requirements and technical resilience in the medium term. Hybrid material composites are also gaining relevance, for example through the combination of wood with mycelium, clay, or carbon. Initial research projects indicate how natural and technical materials can be combined to create sustainable building components.

In the long term, modular systems made from 3D-printed wood are conceivable – for lightweight partition walls, temporary structures, or adaptive facade elements. The aim is not to replace conventional building materials, but to complement them in a targeted manner. As a digitally processable raw material, wood has the qualities that more sustainable, resource-efficient architecture needs: it is ecological, flexible, and adaptable in terms of design.

Conclusion: Wood 3D printing as part of the construction revolution

Additive manufacturing opens up new fields of application for wood as a natural material – from flexible design to resource-saving production. 3D printing with wood is a prime example of the transformation in the construction sector: away from energy-intensive materials and toward bio-based, digital, and individually plannable solutions.

Although the development of sustainable wood filaments and resilient composites is still in the research stage, initial applications and pilot projects are already demonstrating their enormous potential. Whether modular interior elements, biologically inspired façade components, or biodegradable design objects, wood can do more than just look like wood in 3D printing.

As an ecological complement to conventional building materials, 3D wood printing brings new perspectives to architecture: flexible, sustainable, and digitally precise – a true building block for the future of construction.