In the multi-award-winning Airship Hangar Mülheim, visionary structural engineering meets uncompromising sustainability. The complex structural design was carried out using ALLPLAN.

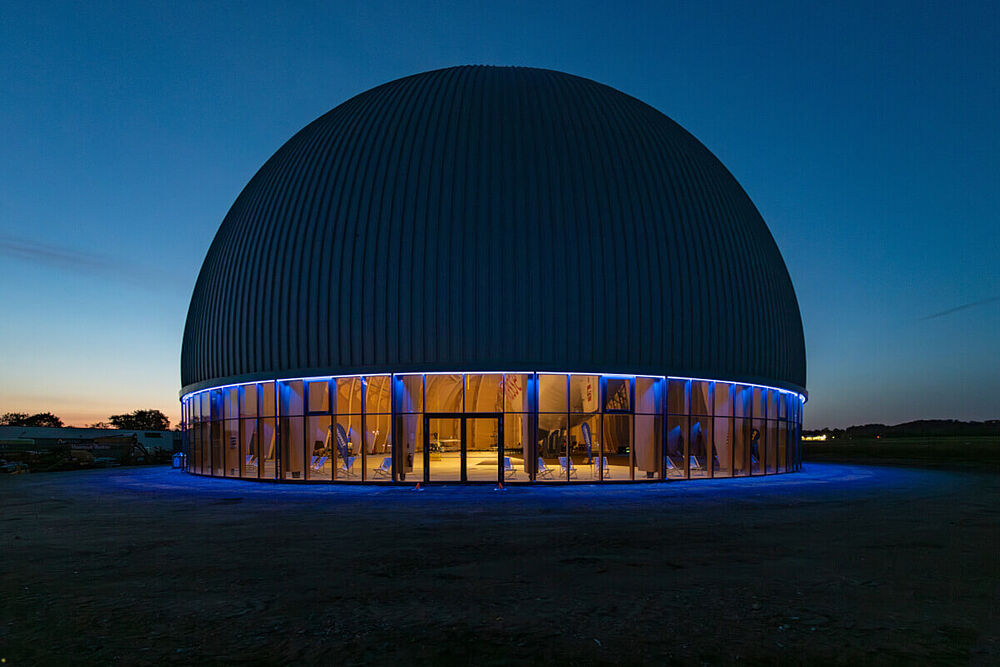

Airships have long ceased to play a significant role in air travel, yet they still hold their place in the skies as flying billboards. Since the early 1970s, WDL Luftschiffgesellschaft mbH has successfully occupied this aviation niche in Mülheim an der Ruhr. Not only do we owe the continued presence of these majestic giants in our skies to the company, but also one of the most exciting structures of our time: the Airship Hangar Mülheim. Since the end of 2022, this breathtaking timber structure has replaced a previous lightweight construction covered in textile fabric, serving as a facility for maintaining and housing the airships over the winter months. The innovative structural design was developed by Ripkens Wiesenkämper – using ALLPLAN.

Innovative Timber Truss Structure for an Old Shape

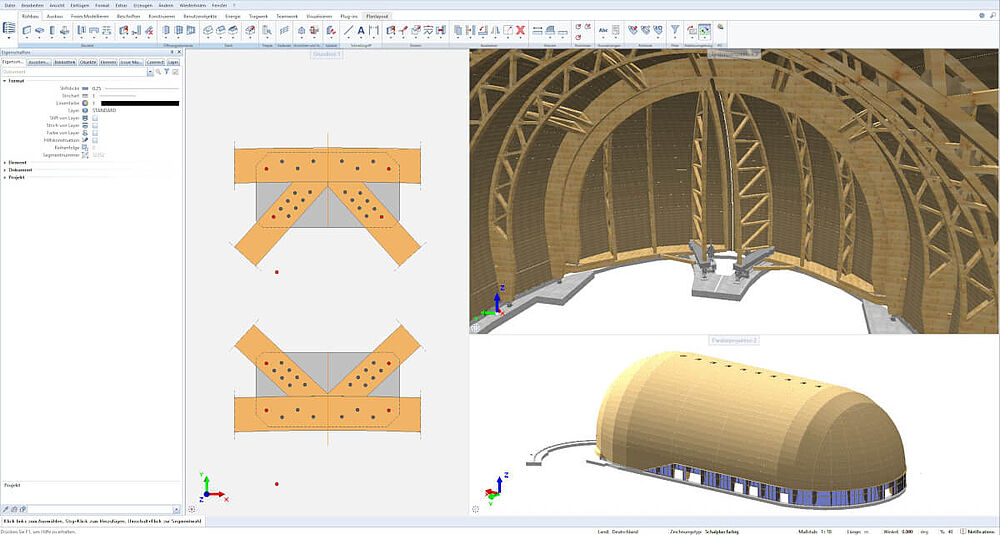

The main challenge in constructing the new hangar lay in complying with building regulations. As permission was granted solely for a replacement structure, the footprint and the curved shape of the original building had to be retained. Unlike the old steel hangar, however, the new one was to be built from timber. To emphasize the industrial architecture aesthetic while conveying a sense of lightness, the architectural firm Smyk Fischer opted for a truss structure. In response, Ripkens Wiesenkämper, together with Marx Krontal Partner, developed a purely timber truss system that, thanks to the use of nearly 600 innovative timber nodes and beams, required no steel at all.

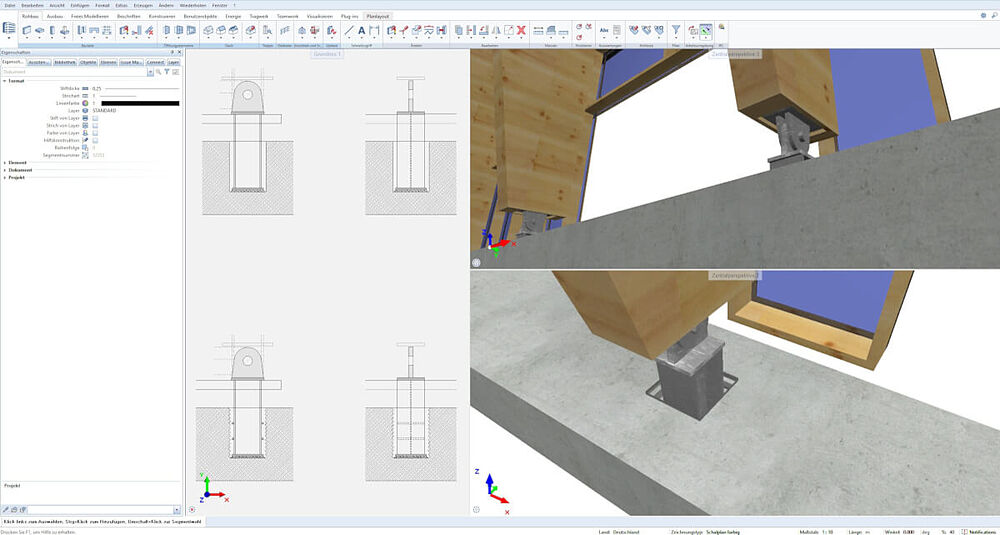

The structural framework consists of fifteen impressive two-hinged arches, each 26 meters high. The top chords and diagonal truss members are integrated into a roof shell made of cross-laminated timber panels. An aluminum standing seam cladding forms the protective outer skin. An extraordinary feature is the huge double-leaf door. To precisely move the massive door wings, each weighing 72 tons, special expertise in handling large movable components was essential. Dr. Schippke + Partner brought this expertise to the project. In collaboration with the hydraulic engineering specialists, they developed a combination of massive hinges and a track system along which the door wings are guided by 80-horsepower electric motors.

Setting New Standards for Sustainable Construction

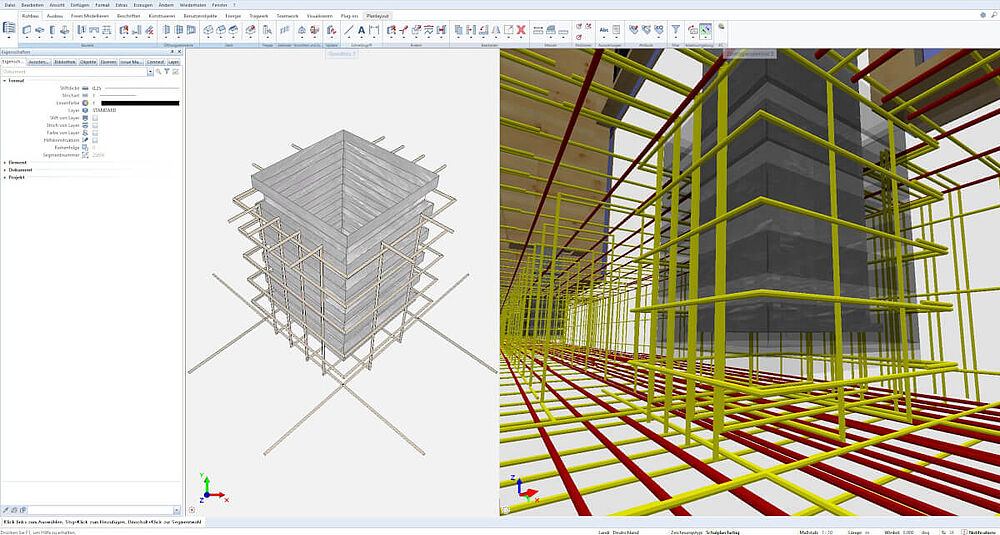

The Airship Hangar Mülheim is not only impressive for its unique structure – it is also setting new benchmarks for sustainable construction. By using a total of around 557 tons of spruce timber, approximately 156 tons of CO₂ were saved compared to a lightweight steel structure. At the same time, the building follows the principles of circular construction: both the timber framework and the aluminum exterior skin are 100 percent dismantlable and can therefore be reused or recycled. To support this, all components of the building have been documented in a building resource passport on the Madaster material database. Parts of the hangar are already “second-hand”: the substructure consists of the foundations from the old airship hall, and the floor uses old concrete slabs salvaged from a former logistics center.

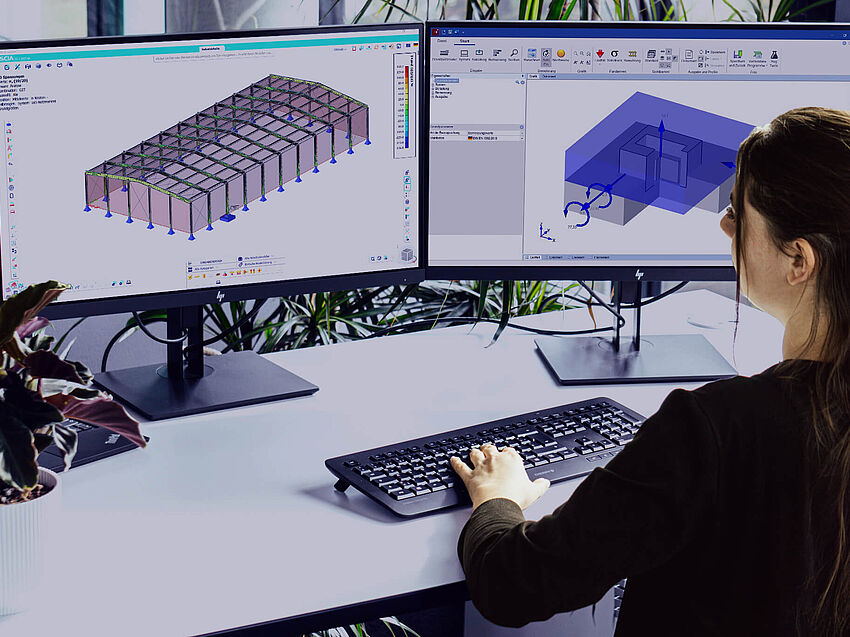

Structural Design with ALLPLAN

Ripkens Wiesenkämper used ALLPLAN for the structural design. To begin with, they created a complete 3D model of the structure, including detailed points such as complex connections and other critical areas. The model was regularly used for clash detection to identify potential conflicts between building components as early as possible. It also served as a basis for precise material and cost estimation. In addition to the structural model for the hangar, the engineers developed a reinforcement model for the hangar’s foundation, which enabled a precise representation of the reinforcement layout and allowed for the direct derivation of formwork and reinforcement drawings. Thanks to cloud-based planning in real time, multiple designers were able to work simultaneously on the same model in ALLPLAN.

More Than Just an Airship Hangar

All in all, the Airship Hangar Mülheim stands as a shining symbol of innovative, sustainable construction with vision. Numerous awards attest to the widespread recognition the building has received within the construction industry and beyond since its completion. In addition to the Ernst & Sohn Engineering Award, the Architecture Award, and the Timber Construction Award NRW, it was most recently honored in 2024 with the German Engineering Award (National Prize). Moreover, the hangar has proven to be a double win for the city of Mülheim. The city not only gains a highly visible, iconic masterpiece of modern timber construction but also a very special event venue. On days when airships are not in operation, the hall can be used – and, above all, experienced – for events hosting up to 1,500 people.

PROJECT INFORMATION AT A GLANCE

| Focus: Structural engineering | Software: ALLPLAN |

| Client: WDL Luftschiffgesellschaft mbH | Structural Design: Ripkens Wiesenkämper Beratende Ingenieure; MARX KRONTAL PARTNER (MKP GmbH) |

| Architects: Smyk Fischer Architekten PartG mbB | Client representative: IBRömling |

| Execution planning & site management: Gronau Plan GbR | Project duration: 2022-2023 |