Three projects demonstrate how ALLPLAN and FRILO, among other things, enable smooth interaction between design, permitting, and execution planning.

Architecture and structural engineering are the two essential pillars on which every (building) element of our built environment is based. The closer the collaboration between these two disciplines, the better for the project. However, efficient integrated planning requires seamless interaction between the respective planning tools. ALLPLAN and FRILO form an ideal pair in this regard, ensuring smooth workflows between architects and structural engineers, while powerful features save considerable time and effort.

Three very different projects highlight some of the advantages that result from combining ALLPLAN and FRILO.

Heidelberg Materials’ Corporate Headquarters: Concrete in All Its Facets

Heidelberg Materials – formerly HeidelbergCement – is one of the largest building materials manufacturers in the world. The new corporate headquarters in Heidelberg, completed in 2020, not only brought together the various departments that had previously been spread across the city. The company also created a vast showroom that showcases the wide range of its products – simply by the building being made of them. The complex consists of three cube-shaped volumes, each five to seven stories high above ground, which interlock and align along a central connecting axis. In total, around 52,000 square meters of gross floor area are available to the approximately 1,000 employees. In addition to modern office spaces, spacious communal areas, a cafeteria, and conference rooms, the ensemble – which is certified DGNB Platinum – also includes generously landscaped outdoor areas.

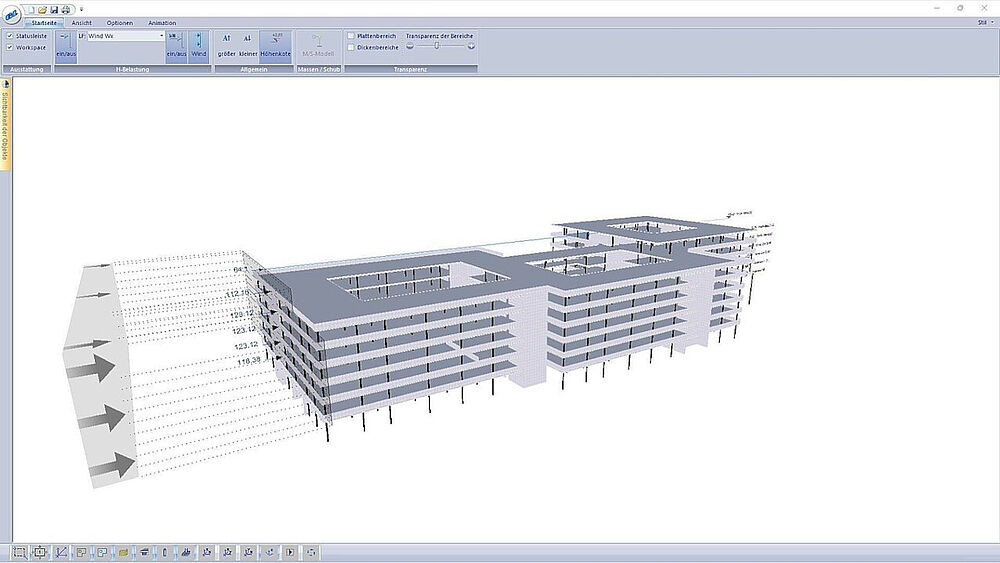

The structural design for the project was handled by the engineering firm Wulle Lichti Walz. The consulting engineers first created the model in FRILO’s GEO program using DXF layers, in order to then determine the load transfer of the entire building within the software. According to partner Oliver Lichti, GEO was a great help, particularly because it allows a quick overview of the vertical load transfer in complex building structures.

While the structural engineers performed component analysis and dimensioning in FRILO, the draftspeople at the Mosbach office created a detailed 3D model of the headquarters in ALLPLAN. Based on the finite element (FE) calculations carried out in the slab program PLT, the structural engineers then generated ASF files in FRILO and transferred them to ALLPLAN to support the fast and precise creation of reinforcement drawings. In total, around 3,600 reinforcement drawings and 2,000 formwork plans were produced in ALLPLAN.

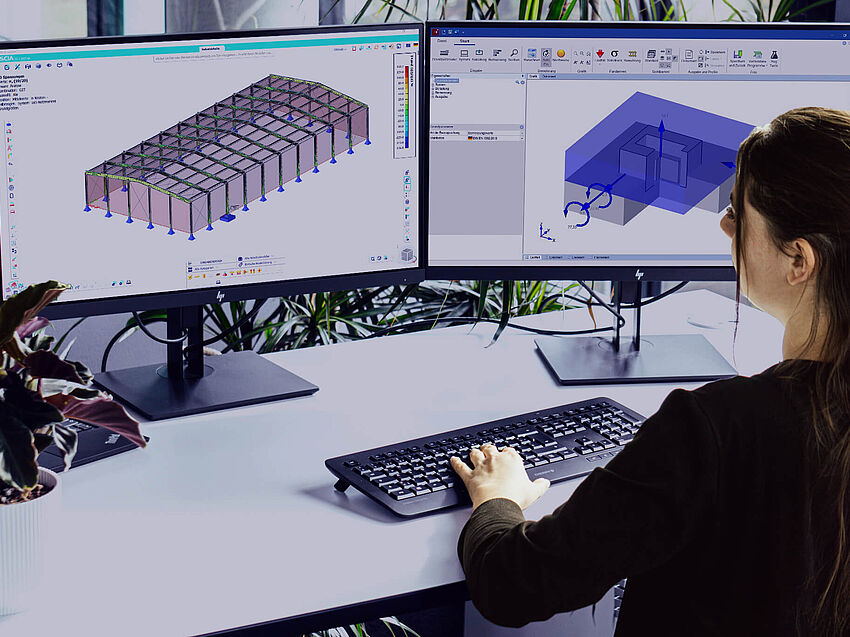

100% BIM Planning: Gottschall + Sohn Multipurpose Building

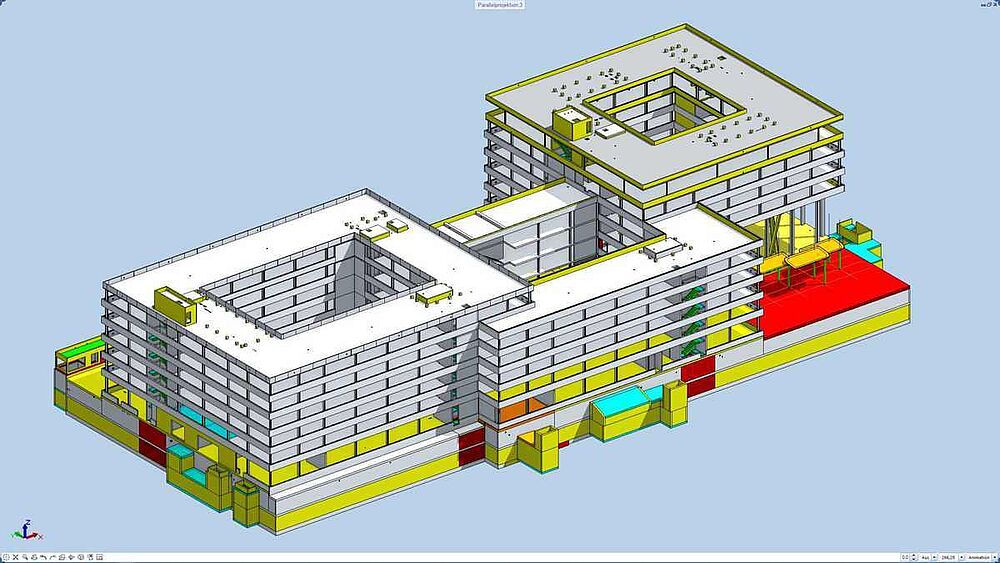

For a new multipurpose building for the building services wholesaler Gottschall + Sohn in Grevenbroich, the planning office baues + partner from Korschenbroich was responsible for the architectural and structural design, as well as the thermal insulation, soundproofing, and fire protection. It was a perfect opportunity to fully test the BIM methodology. The new build expands the company’s existing headquarters and includes, alongside a large sanitary showroom, various training and seminar rooms, a cafeteria and kitchen, and a single-stream daycare center operated by the city of Grevenbroich. Structurally, the building is a two-story reinforced concrete frame construction with a load-bearing reinforced concrete floor slab. Reinforced concrete shear walls extending across both floors provide structural stability. Depending on acoustic and fire protection requirements, the different usage areas are separated by masonry walls.

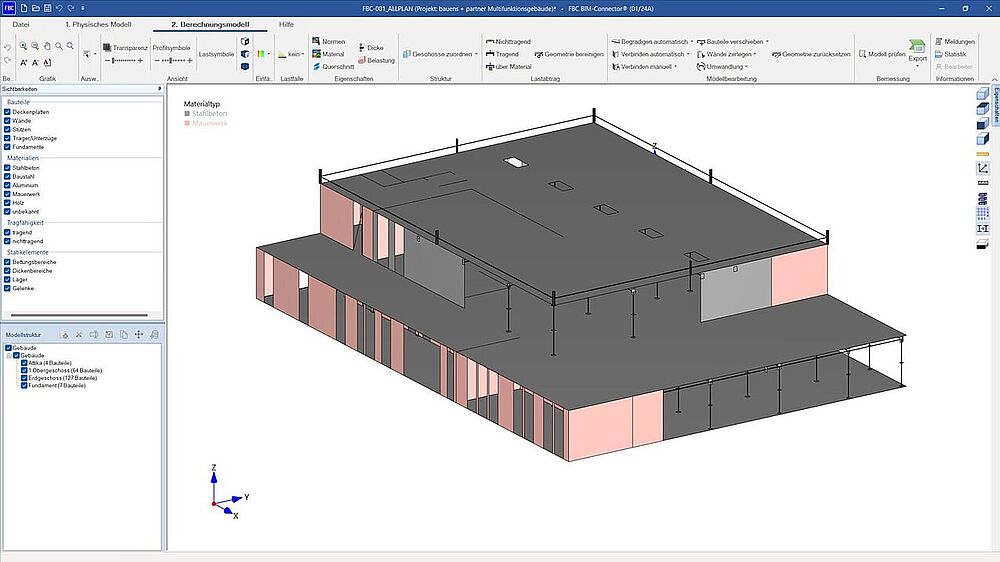

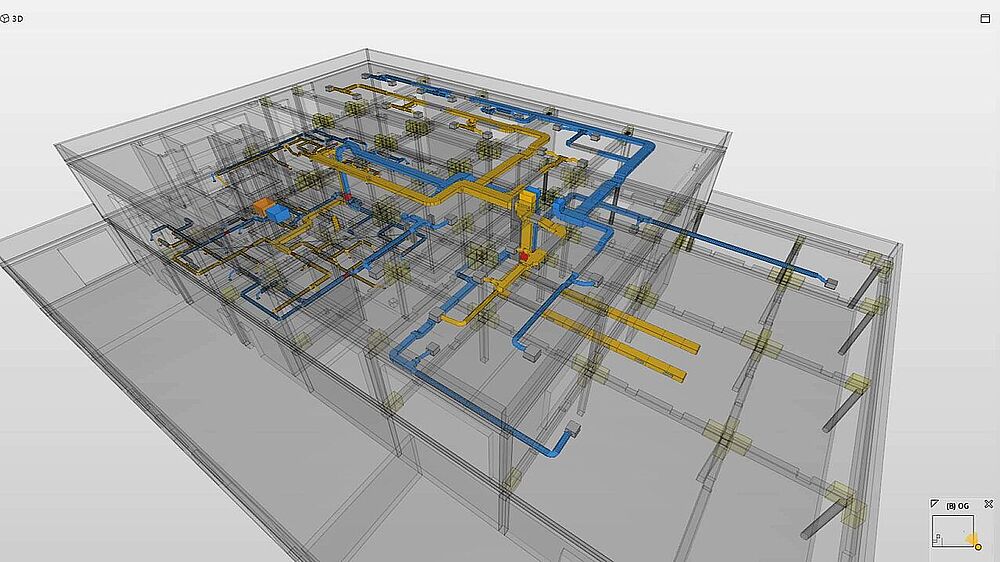

The foundation for the end-to-end BIM process was a structural analysis model created in Archicad. For the structural calculations, the model – reduced to its load-bearing components – was first exported as an SAF file and transferred to the FRILO BIM-Connector®. After refining the 3D model to ensure accurate load transfer, the vertical loads and seismic loads were determined using FRILO’s GEO module. Since a verifiable structural analysis requires a general arrangement plan, the draftspeople created the structural engineering discipline model in ALLPLAN for the execution planning phase as soon as the first calculation results from FRILO became available. Step by step, the results from FRILO were incorporated into the ALLPLAN model. Once the general arrangement plan was complete, baues + partner then generated the formwork and reinforcement drawings in ALLPLAN.

Living in the Vierseithof in Traunstein: Sustainable Housing Provision

Living in Traunstein may be idyllic, but due to high rents, it’s not necessarily affordable for everyone. For this reason, the Traunstein housing association is currently building what’s known as the “Vierseithof” in the new Seiboldsdorf development. The project consists of four multi-family buildings with a total of 50 apartments ranging from one to five rooms. Of these, 33 are intended for citizens with low to medium incomes and are subsidized through income-based funding (EOF) provided by the Free State of Bavaria.

At the same time, the project – designed to meet KfW40 standards – is heavily focused on ecological and social sustainability. In addition to heat pump technology and photovoltaics, it features attractive communal spaces such as a neighborhood café and a shared garden.

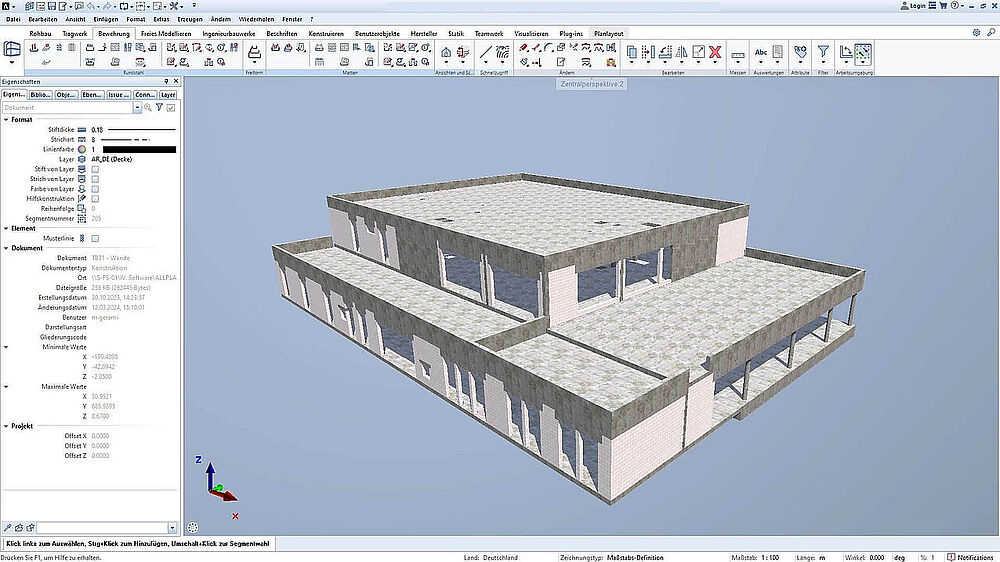

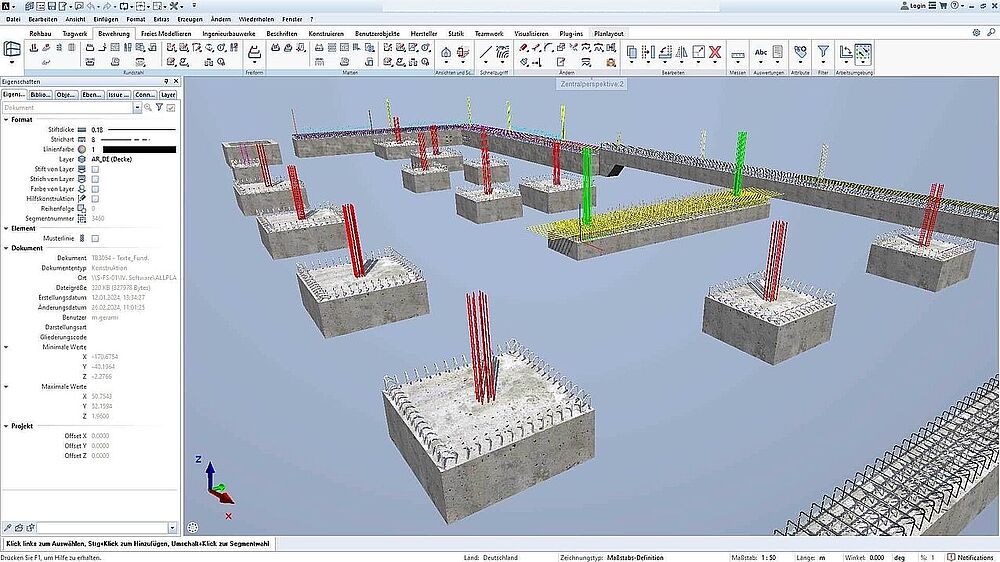

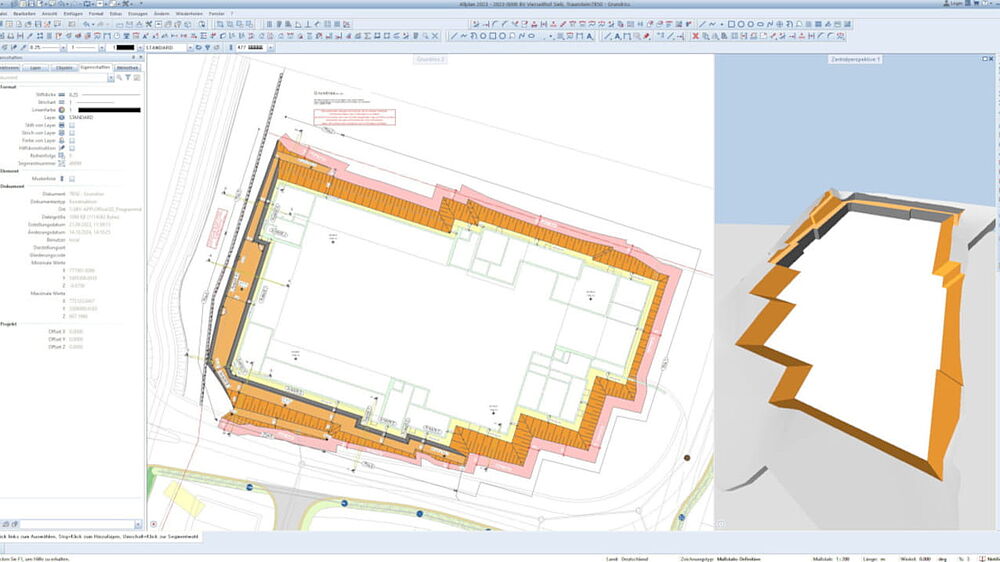

The local engineering firm concon was commissioned with the structural design, building envelope and performance design, and execution planning for the Vierseithof. The BIM project was based on an architectural model created in Archicad by the firm Guggenbichler + Wagenstaller, which the engineers used as a reference to model their own structural engineering discipline model in ALLPLAN. According to Florian Lindner, managing partner at concon, this model served as a basis for the formwork and reinforcement planning, for the development of the sound and fire protection plans, and for energy consulting throughout the project. It was also essential for producing a verifiable structural analysis.

To that end, the discipline model was exported via IFC interface to FRILO’s BIM-Connector®. Because materials and component classifications had already been accurately assigned in ALLPLAN, the physical model could be reduced to a calculation model at the push of a button.

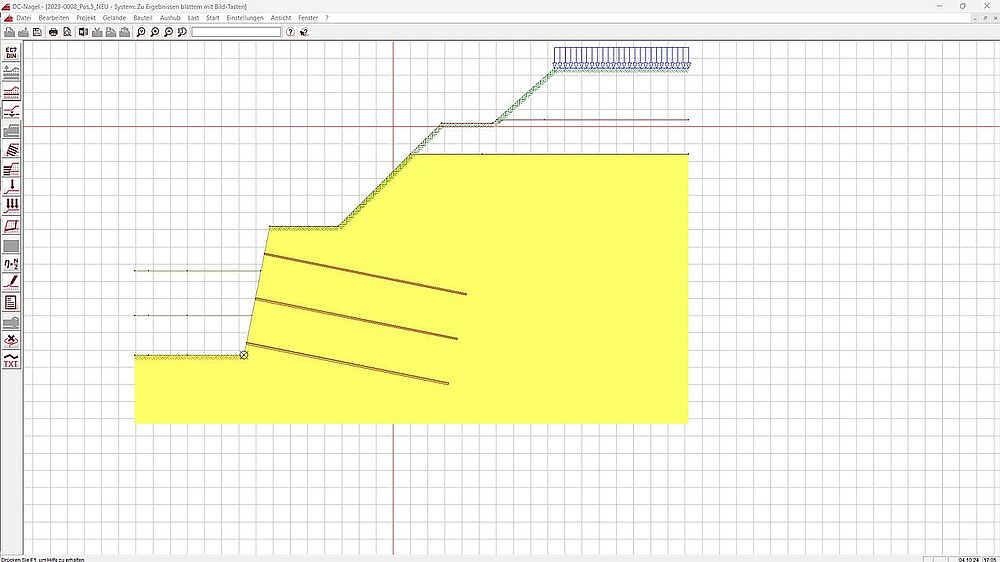

In fact, ALLPLAN and FRILO were used in tandem twice on the Vierseithof project. The responsible company, GSGE GmbH, also created the excavation support plan as a 3D model in ALLPLAN. This model was used not only for deriving quantities, but also as the basis for later calculations of the excavation slope’s stability using ALLPLAN’s DC-Software.