Enhancing Linear Infrastructure Design: A Real-World Workflow with ALLPLAN Civil and ISTRAM

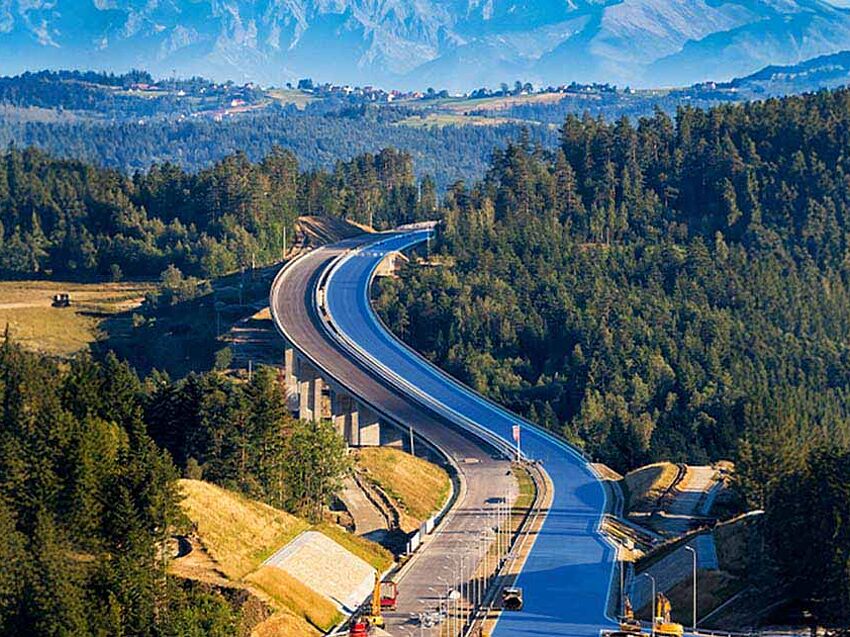

In the heart of Croatia, a transformative infrastructure project is reshaping the nation’s railway network, forging a faster and more efficient connection to Hungary. The 42km double-track railway modernization is a vital link in the European transport network, designed to improve freight transport efficiency and reduce travel times for passengers.

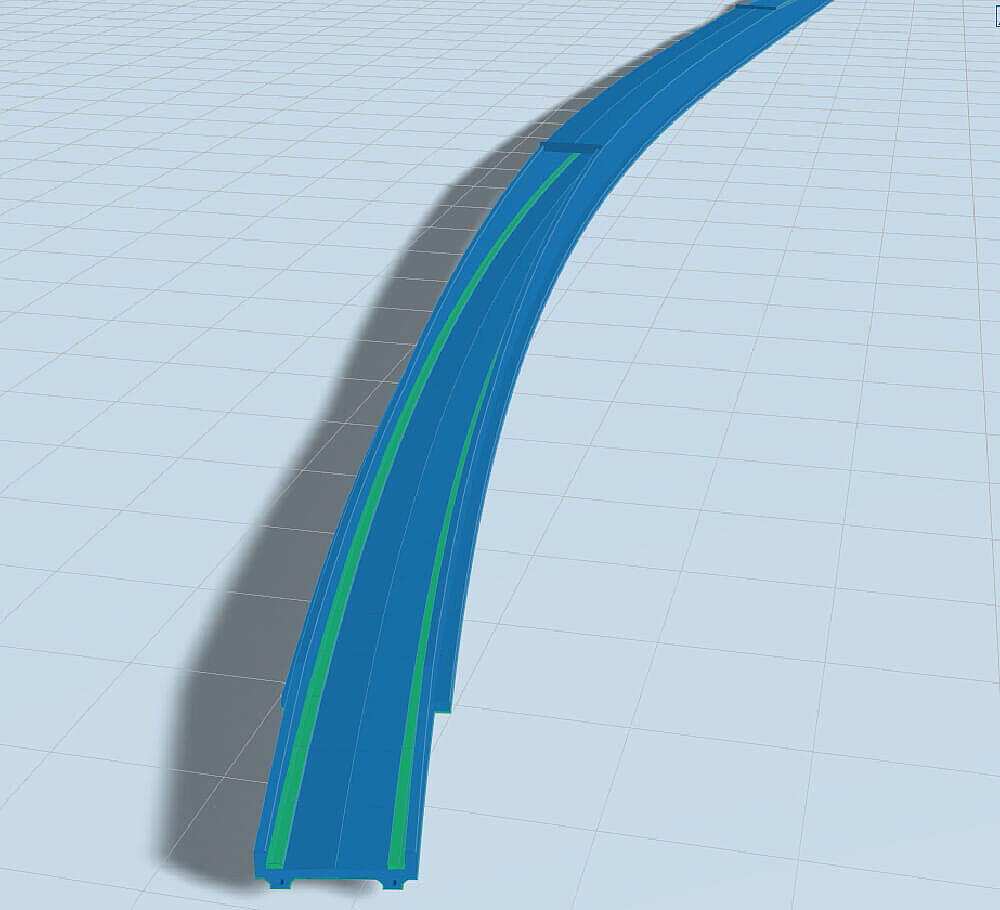

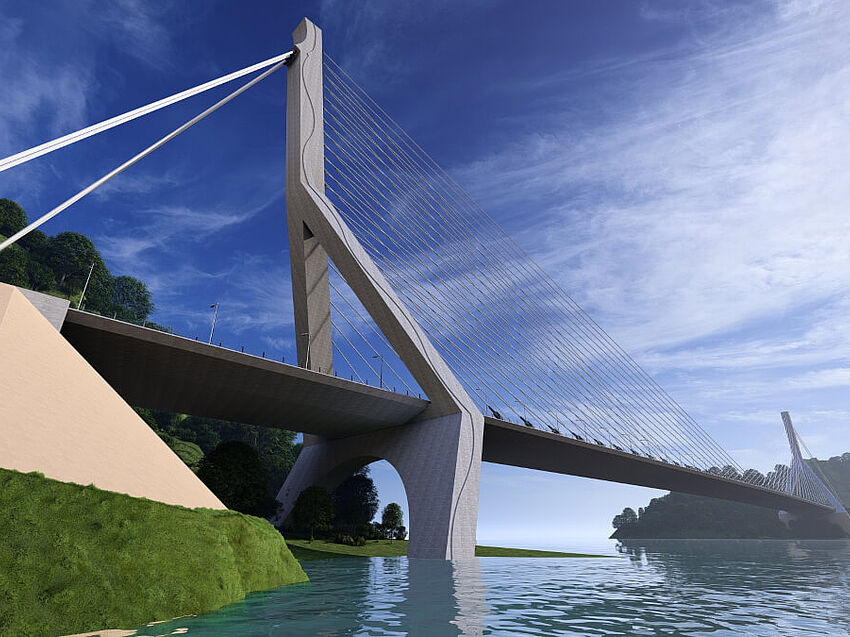

The sheer scale of the project is striking. It involves not only upgrading an existing railway but also constructing a brand-new parallel line, integrating major structures such as two semi-integral railway viaducts, multiple cut-and-cover tunnels, and a critical steel truss bridge over the Drava River, built using the incremental launching method (ILM). Beyond the engineering complexity, the project must align with modern railway standards, ensuring precise alignments and structural integrity.

At the forefront of this ambitious effort are Cengiz Insaat, the construction company responsible for delivering the project, and Radionica Mostova, the design firm overseeing structural engineering. With an ambitious completion target of late 2025, the team must overcome multiple logistical, environmental, and technical hurdles. The question is: how do they overcome these challenges while maintaining efficiency and precision? The answer lies in advanced digital modeling and collaboration, key areas where ALLPLAN is making a significant impact.

Conquering Engineering Hurdles

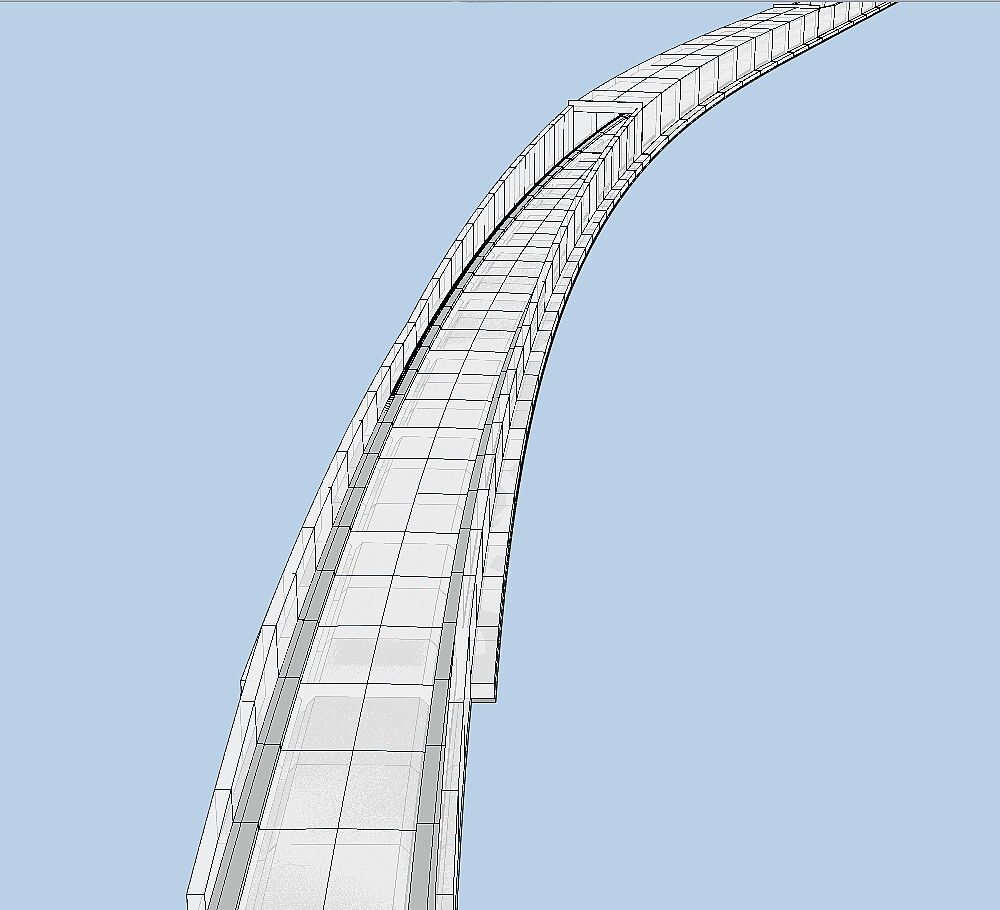

Designing a railway of this scale presents numerous challenges, but perhaps none more complex than the viaducts and the Drava River bridge. These structures must not only support heavy rail loads but also accommodate shifting terrain, high environmental loads, and strict construction tolerances.

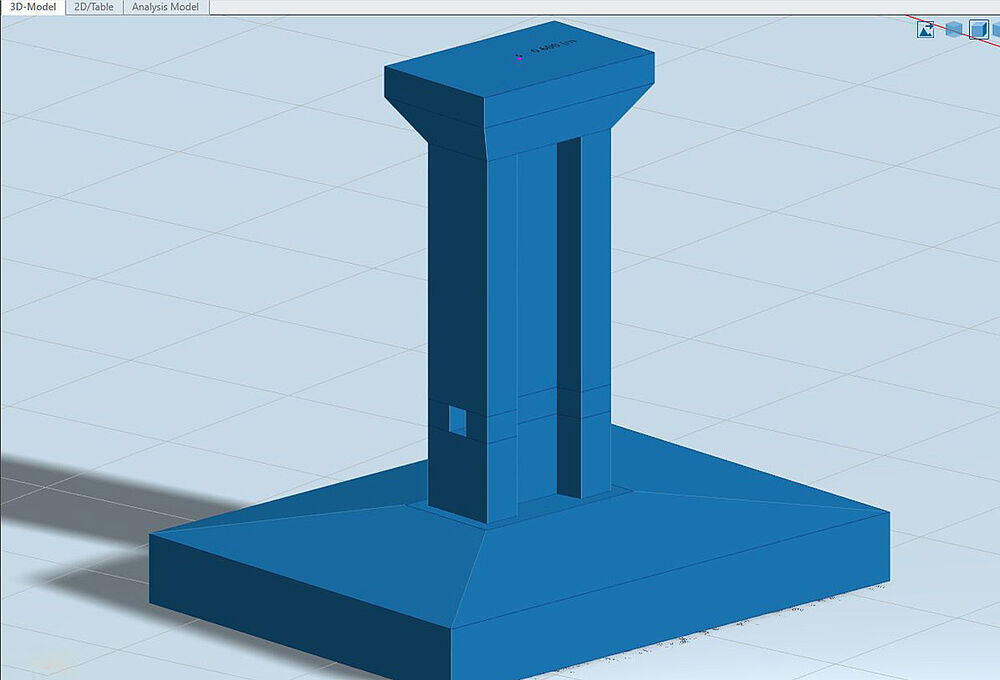

One of the most difficult aspects was optimizing the design of the Carevdar viaduct, from its foundation to its deck. The team needed to balance structural efficiency with material optimization while ensuring stability. Another major challenge was the Drava Bridge, a 4000-ton steel structure requiring meticulous planning for its ILM construction method.

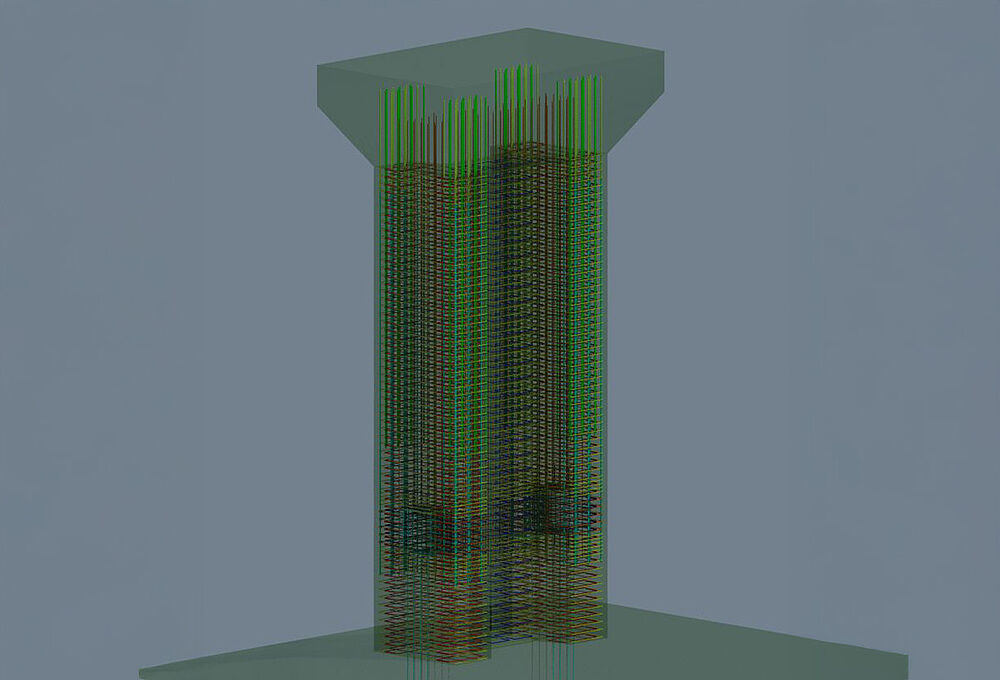

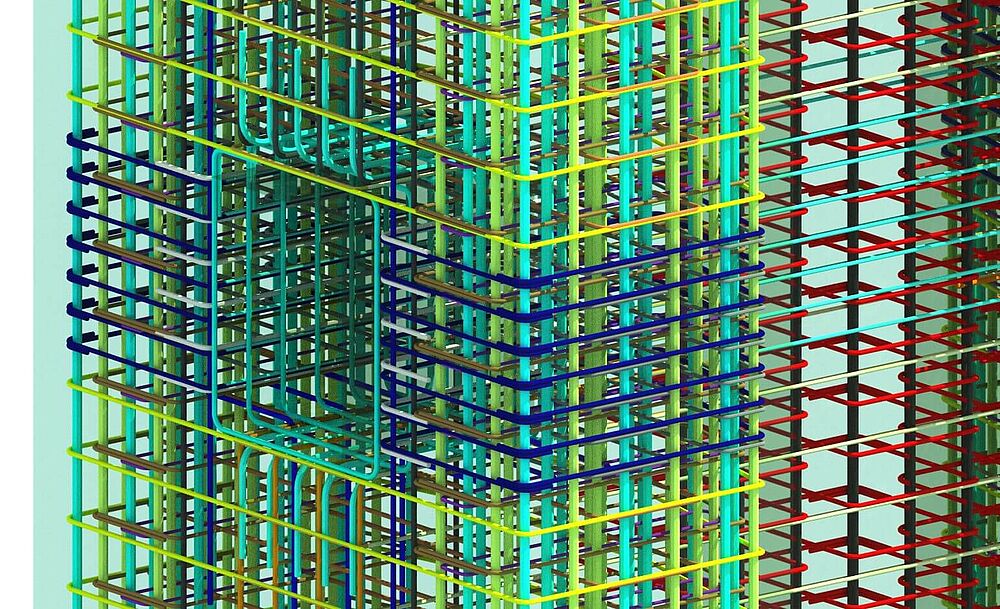

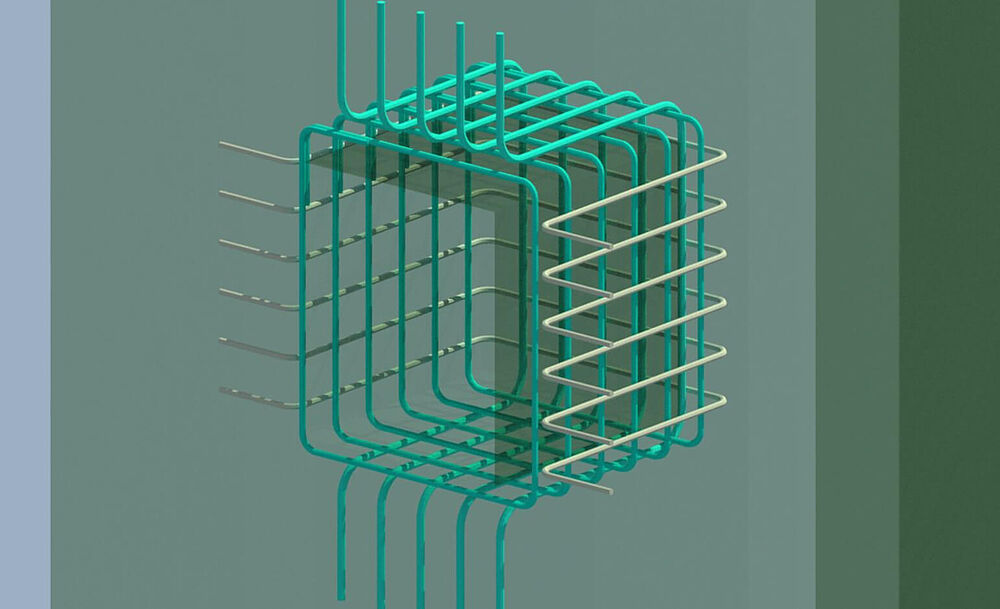

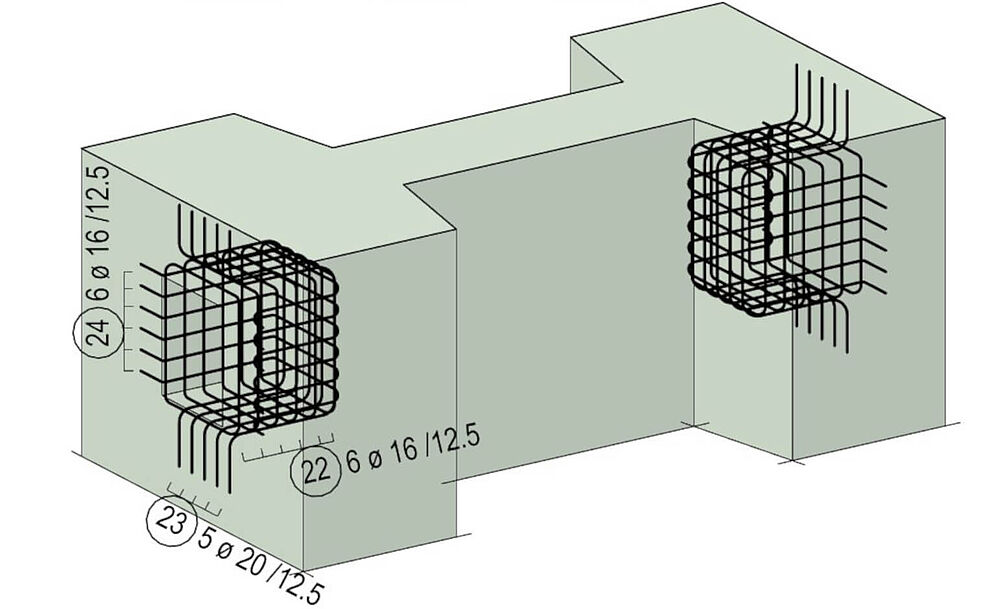

This is where ALLPLAN played a pivotal role. The software’s parametric modeling capabilities allowed engineers to refine and adjust viaduct and bridge designs with precision, ensuring alignment with real-world site conditions. The reinforcement detailing tools proved invaluable for the prestressed sections of the structures, where a combination of longitudinal and transverse tendons required careful planning. Collision detection in ALLPLAN helped engineers identify and resolve reinforcement conflicts early, preventing costly rework during construction.

“Prestressing is always complex, but for this project, the detailed modeling of tendons was critical,” said Rahela Mikulic, Bridge Designer at Radionica Mostova. “Each tendon has its own curvature, and ALLPLAN allowed us to model these with high accuracy, ensuring everything fit correctly.”

With these tools, the team successfully optimized structural elements while maintaining compliance with international railway standards, setting the stage for efficient construction.

From Design to Reality: Construction on the Ground

With the designs finalized, the challenge shifted from modeling to execution. One of the most demanding aspects was coordinating construction phasing – ensuring that each element was built in the correct sequence while minimizing disruption to existing railway operations.

For the construction teams on-site, understanding the exact placement of reinforcement and pre-stressed elements was critical. Misalignment could lead to structural instability or delays. Using ALLPLAN’s 3D modeling and phased construction visualization, engineers were able to provide site teams with clear, step-by-step guidance for reinforcement placement and prestressing sequences.

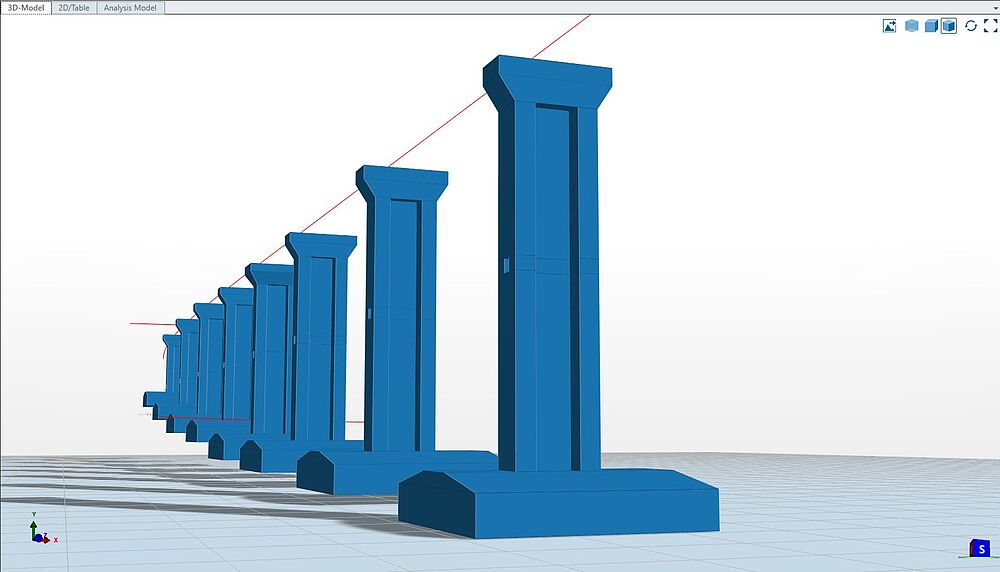

Templates within ALLPLAN were also essential in accelerating workflows. The repetitive nature of elements like piers meant that traditional manual modeling methods would have been time-consuming and prone to inconsistency. Instead, engineers used template-based designs to quickly replicate elements while ensuring precise dimensions and reinforcement layouts. “We had 14 piers on this viaduct, ranging in height from 17 to 28 meters,” explains Kresimir Ilic, Chief Designer at Radionica Mostova. “Using templates in ALLPLAN significantly sped up the process, making our workflow far more efficient.”

Beyond the structures themselves, seamless interdisciplinary collaboration was crucial. With multiple teams working on structural, mechanical, and electrical components, ALLPLAN’s integrated BIM workflows ensured that models remained synchronized across disciplines. This reduced clashes between structural reinforcements and embedded elements such as catenary poles, drainage infrastructure, and pedestrian underpasses.

As construction progresses, the benefits of this digital-first approach have become even clearer. Engineers can quickly adapt to on-site conditions, adjusting reinforcement layouts or modifying alignment details as needed – all while maintaining precision and compliance.

A Model for Future Infrastructure

With the railway project now over 60% complete, ALLPLAN’s advanced digital modeling tools have played a crucial role in overcoming some of its most complex engineering challenges. From optimizing structural designs and reinforcing prestressed elements to ensuring seamless coordination between teams, the software has been instrumental in keeping the project on track.

But beyond just this project, the use of BIM-driven infrastructure design represents a broader shift in railway engineering. As transport networks across Europe undergo modernization, digital modeling tools like ALLPLAN will be essential for streamlining workflows, reducing errors, and ensuring that projects are delivered efficiently.

“This project required full collaboration between engineers, designers, and site teams,” adds Emre Yolal, Project Manager at Cengiz Insaat. “By working in 3D, we avoided unknowns during construction, which helped us stay on schedule.”

With the project set for completion in late 2025, it serves as a model for how modern infrastructure should be designed and executed. The lessons learned here – leveraging parametric modeling, enhancing collaboration, integrating reinforcement detailing, and the benefits of digital tools like ALLPLAN – are paving the way for more efficient, data-driven railway projects in the future.