Enhancing Linear Infrastructure Design: A Real-World Workflow with ALLPLAN Civil and ISTRAM

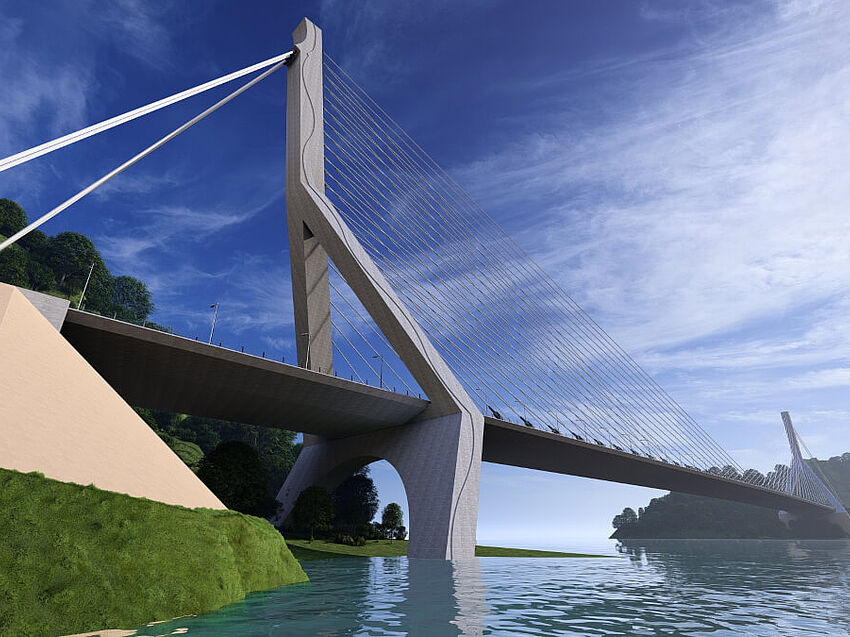

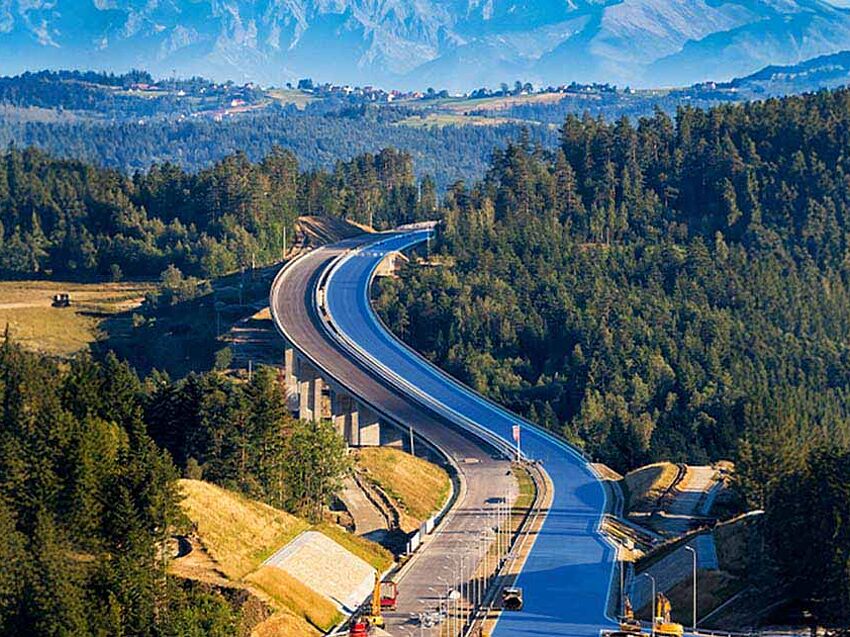

The Sibiu-Făgăraș Highway is more than just another road project. Running for 75 kilometres through central Romania, it connects the Transylvanian Plain to the Southern Carpathians – a vital link in the region’s transport network. But the terrain is far from simple. Multiple rivers, streams, and underground water sources meant an extraordinary number of crossing structures, each with its own engineering demands.

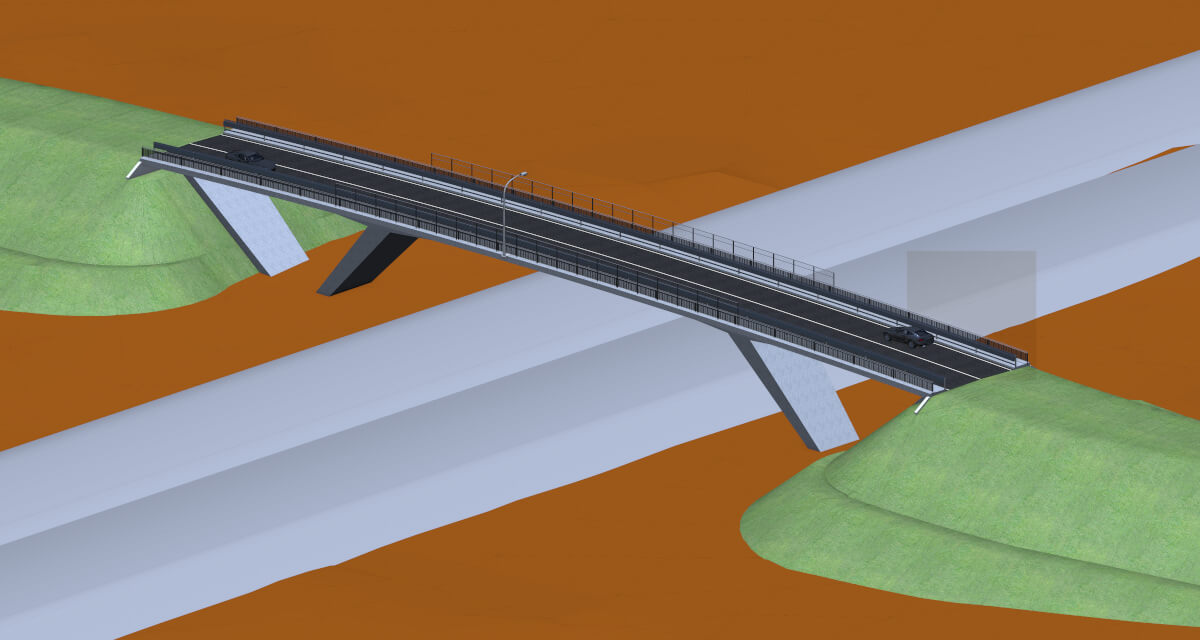

In total, the project involves 111 bridges, including 27 steel bridges (12 of them arch bridges), 23 reinforced concrete overpasses, and numerous retaining walls and culverts. With one year for design and three for construction, accuracy, coordination, and efficiency was critical to success. For MAKYOL Construction, the contractor responsible for delivering the project, it was clear that a traditional 2D approach would not be enough.

Overcoming the Pitfalls of 2D Design

On this project, complexity lives in the details. While the initial designs provided a starting point, they were delivered in 2D – a format that doesn’t translate well when dealing with geometrically complex structures. With the large number of structures on the project, MAKYOL’s planning group quickly saw the risks: reinforcement details open to interpretation, inconsistencies that could cause manufacturing errors, and gaps that might leave site crews guessing.

The arch bridges, with their intricate reinforcement geometry, were especially vulnerable to misinterpretation. Similarly, the overpasses required highly precise rebar schedules to avoid delays in fabrication and installation. With the demanding design and construction schedule, there was no margin for error. To keep the project on track and avoid costly rework, MAKYOL needed a faster, more accurate, and fully buildable approach – one that would bridge the gap between design and construction from day one.

Selecting the Right Tool for the Job

For MAKYOL, the solution needed to do more than just replace 2D drawings with 3D models – it had to connect the design office with the realities of the construction site. ALLPLAN Civil offered exactly that.

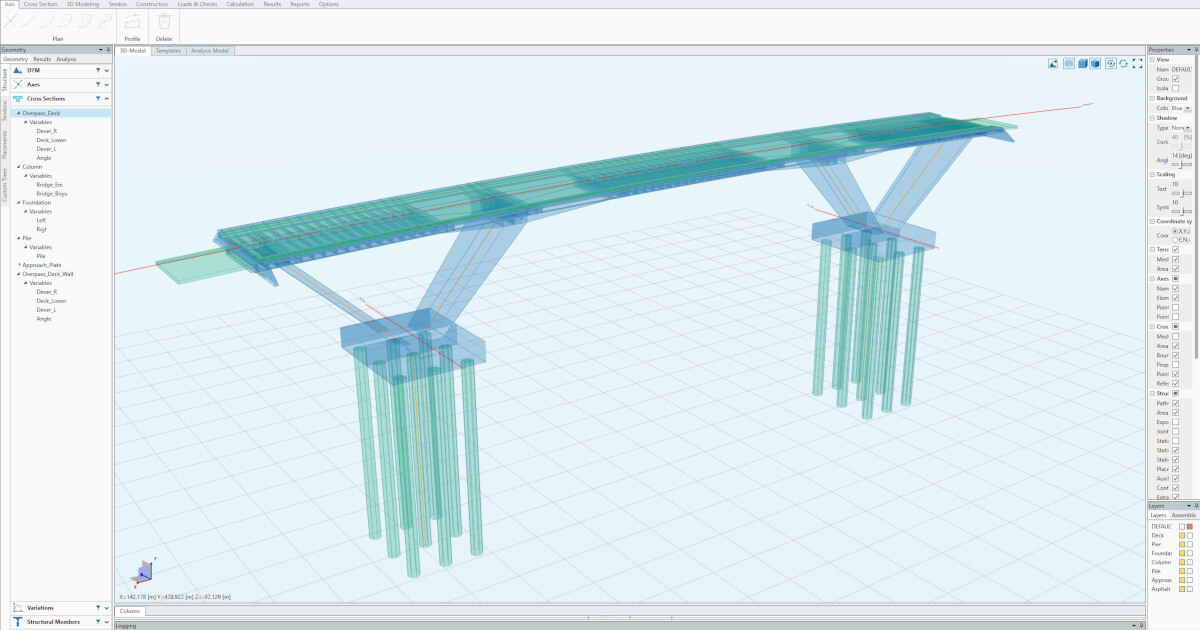

By re-modeling the overpasses in 3D, the team could visualize every element with complete clarity, from the overall geometry to the placement of each rebar. This level of detail was particularly valuable for communicating complex reinforcement and construction requirements to the field.

Equally important, reinforcement schedules could be generated directly from the model and sent to manufacturers, ensuring fabrication was accurate the first time. With clearer communication, fewer site queries, and designs that were construction-ready from the outset, ALLPLAN Civil aligned perfectly with MAKYOL’s goal: to deliver a challenging infrastructure project on time, on budget, and without compromise.

Parametric Modeling in Action

One of the project’s most significant time-savers came from ALLPLAN Civil’s parametric modelling capabilities. For the 23 overpasses, the team created a single parametric model that served as the master template.

With key parameters – such as span length, foundation widths, and deck height – defined in editable fields, each overpass could be generated by simply updating these values. This approach not only saved weeks of manual modeling but also ensured every structure followed consistent design principles.

When late changes were required, updates flowed seamlessly through the model, keeping the design in sync with construction needs.

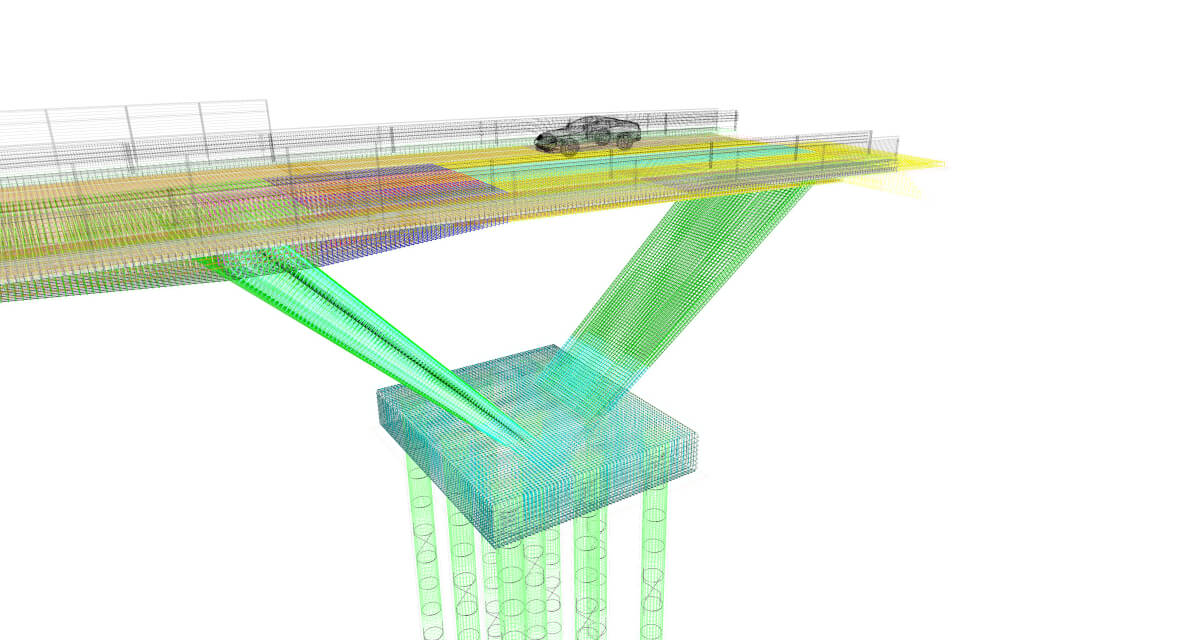

Reinforcement Detailing and BIM2Field

Reinforcement accuracy is a common challenge in bridge projects. With ALLPLAN Civil, the MAKYOL team was able to model the reinforcement of the overpasses in 3D, ensuring complete alignment with the bending schedules. These schedules were generated automatically and sent directly to the manufacturers, who could then deliver pre-bent, error-free reinforcement to site.

For the field teams, this meant clearer, more intuitive instructions. Perspective 3D views and detailed sections helped site crews quickly understand placement, reducing delays from queries or misinterpretations.

These benefits extended to problem-solving. When an issue arose on a steel bridge concerning the installation of formwork beneath a concrete deck, the team quickly created a 3D model of the proposed solution. This visual aid made it easier to communicate the fix to all stakeholders and get approval to proceed without delay.

From Office to Field: Real Outcomes

For the overpasses, the combination of parametric modeling and precise reinforcement detailing delivered tangible results. Designs were consistent, buildable, and easily adapted to changes. Manufacturers received exact bending schedules, eliminating costly fabrication errors, while on-site teams worked from clear, visual documentation, reducing queries and rework. Issues were also resolved faster with 3D models that explained solutions at a glance. By connecting design, manufacturing, and construction in a single workflow, ALLPLAN Civil helped MAKYOL keep the Sibiu-Făgăraș Highway project on track – proving that digital precision can drive real-world efficiency.

The Benefits of a Fully Connected Workflow

The Sibiu–Făgăraș Highway shows how the right tools can turn a complex infrastructure challenge into a coordinated, efficient build. By shifting from 2D plans to a fully connected, parametric workflow for the overpasses in ALLPLAN Civil, MAKYOL eliminated common points of failure – from unclear reinforcement details to time lost on rework. The ability to adapt designs quickly, deliver precise schedules to manufacturers, and give site teams intuitive 3D visuals meant the project moved forward with fewer delays and greater confidence. For large-scale, multi-structure projects, this approach is more than a productivity boost – it’s a blueprint for delivering complex infrastructure on time, on budget, and to the highest standards.