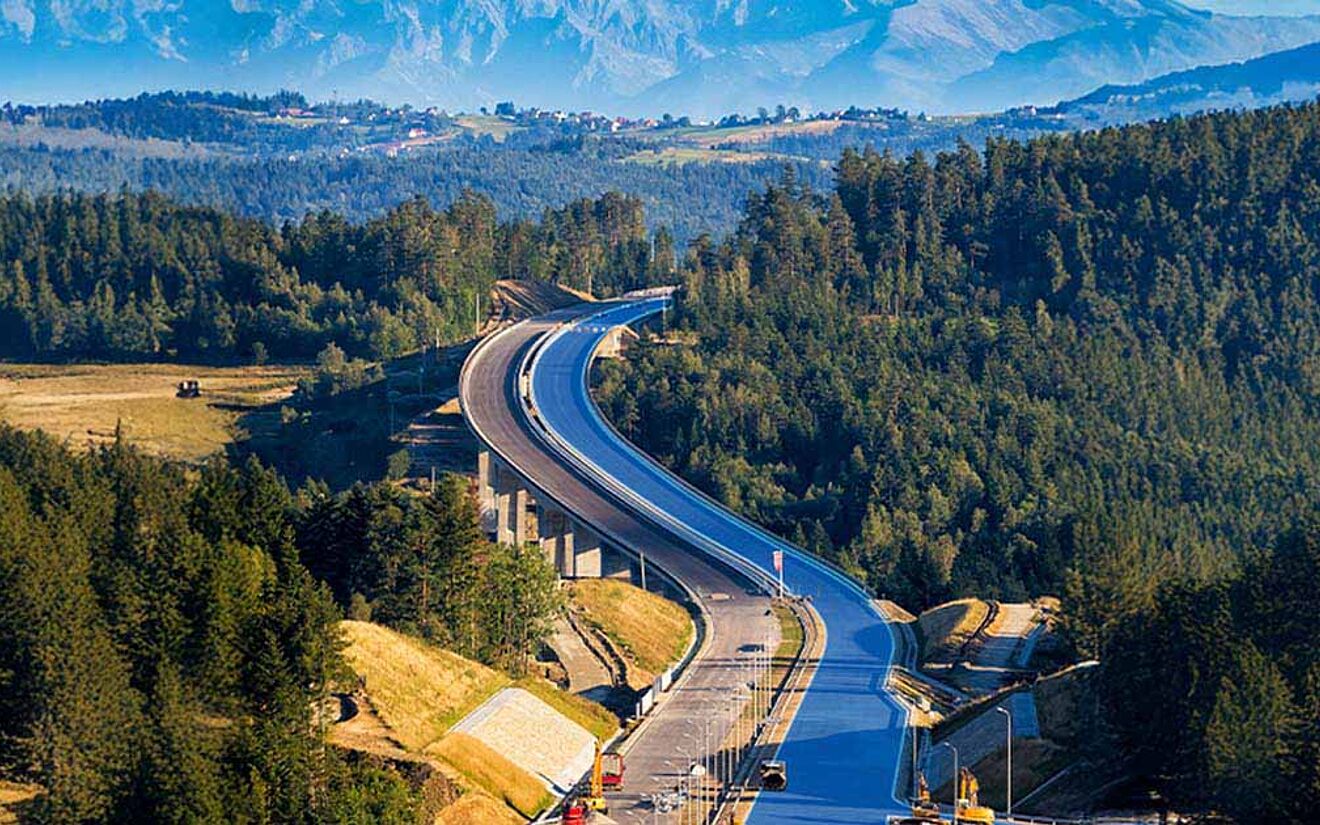

Road to Milano–Cortina 2026 – What the Olympics reveal about resilient infrastructure

Across Europe, thousands of bridges, roads, and tunnels built between the 1960s and 1980s are approaching the end of their service life. What was once the pride of post-war development is now a complex challenge for engineers, owners, and operators alike. The focus of investment is shifting – away from new construction and toward maintenance and renewal.

In summary: > By 2040, up to 70% of infrastructure budgets are expected to focus on preserving existing assets. > Digital tools such as BIM, digital twins, and integrated data platforms enable proactive, data-driven maintenance. > These tools improve condition assessment, sustainability, cost control, and long-term performance. > ALLPLAN’s Best Practice Guide outlines how engineers and public authorities can build digital maturity and turn infrastructure modernization into a strategic opportunity. |

By 2040, experts predict that up to 70 percent of infrastructure budgets will go toward preserving existing assets. This change represents both a warning and an opportunity: the future belongs to those who can deliver smarter, data-driven, and sustainable maintenance solutions.

The Maintenance Challenge

For decades, infrastructure investment focused on expansion – new motorways, new bridges, new tunnels. Today, the focus has moved decisively toward preservation. Ageing assets, limited budgets, and rising sustainability requirements are forcing the sector to rethink long-established processes.

Maintenance is now the growth market in infrastructure. But successful modernization requires a very different approach from new construction. Instead of blank-sheet design, engineers must deal with existing structures of uncertain condition, incomplete documentation, and demanding regulatory frameworks.

Ageing infrastructure also brings a series of pressing questions:

> How can engineers accurately assess the condition of decades-old assets?

> How can they plan cost-effective interventions while meeting environmental, social, and governance (ESG) goals?

> And how can they ensure safety and service continuity while projects are under way?

Traditional, fragmented workflows often fall short of answering these demands. Paper-based inspections and manual data transfers create blind spots and inefficiencies. Meanwhile, the demand for transparency, accountability, and sustainability has never been higher.

The solution lies in embracing digital methods – enabling teams to move from reactive maintenance to proactive, predictive management of infrastructure assets.

Digitalization: The Key to Smarter Maintenance

Modern tools such as Building Information Modeling (BIM), digital twins, and integrated data platforms are changing how infrastructure projects are planned and delivered. They allow engineers to visualize, simulate, and manage every phase of an asset’s lifecycle with unprecedented accuracy.

With reliable data at the core, project teams can make faster, better-informed decisions – from condition assessment and design to construction, operation, and beyond. The result is not just reduced downtime and lower costs, but more resilient, sustainable networks built for the long term.

This digital shift is redefining what “maintenance” means. It’s no longer just about repairing what’s broken; it’s about using insight and innovation to extend the life of critical assets, reduce carbon impact, and maximize the return on public investment.

A Growing Market – and a Strategic Opportunity

The numbers tell a clear story. As maintenance spending grows, so too does the demand for specialist expertise. Firms with the right digital capabilities are already winning more complex rehabilitation and modernization projects.

The most successful players are those that combine traditional engineering know-how with advanced digital tools – bringing together accurate as-built data, real-time collaboration, and performance analysis. These capabilities are no longer optional; they’re the foundation for competitiveness in a maintenance-driven market.

That’s why we’ve developed our new Best Practice Guide – Modernization and Renewal of Transportation Infrastructure. The guide distills key insights, digital strategies, and expert perspectives to help infrastructure professionals adapt to this new reality and position their firms at the forefront of a rapidly transforming market.

As the guide explains, modernization is not just a technical exercise but a strategic one. It’s about building the digital maturity to handle today’s challenges while preparing for the next wave of innovation – from AI-assisted design to condition-based maintenance supported by sensor data.

Inside the Best Practice Guide

Rather than offering theory, ALLPLAN’s Best Practice Guide provides actionable insights and real-world context. It explores how leading infrastructure professionals are approaching the modernization of transportation assets and what digital workflows are helping them deliver better results.

Within its pages, readers will find guidance on aligning maintenance strategies with long-term sustainability goals. There are also insights from engineering experts using BIM and data-driven planning, as well as practical examples of how digital tools can improve accuracy, safety, and efficiency.

It’s an essential read for engineers, consultants, and public authorities who want to understand not just why modernization matters, but how to make it work in practice.

Building a Sustainable Future, Together

Modernizing transportation infrastructure is one of the defining challenges of our time. It requires collaboration across disciplines, clear data from every stage of the asset lifecycle, and digital workflows that support both performance and sustainability.

ALLPLAN is committed to helping engineers and project teams meet these goals – combining decades of engineering expertise with state-of-the-art BIM solutions designed for the entire design-to-build process.

The Best Practice Guide is part of that commitment. It offers a concise yet insightful look at how digital transformation is reshaping infrastructure maintenance – and how forward-thinking professionals can stay ahead of the curve.

Download the Best Practice Guide: Modernization and Renewal of Transportation Infrastructure to explore expert insights, emerging trends, and digital strategies for smarter, more sustainable project delivery.