From Design to Field: How ALLPLAN Civil Streamlined a Complex Highway Project in Romania

Tunnel engineering is among the most demanding areas of civil design. Every curve, geological shift, and excavation phase adds complexity. For years, engineers relied on 2D drawings and manual conversions to 3D, a fragmented process that slowed productivity and invited inconsistencies.

Yüksel Proje – a Turkish engineering and consultancy firm active in more than 40 countries – sought a better way. Known for its focus on digital innovation, the company partnered closely with ALLPLAN to test new capabilities for tunnel design. The result was a faster, more flexible, and more accurate workflow powered by ALLPLAN Civil 2026.

Rethinking Tunnel Design

Tunnel projects pose unique technical challenges that have historically pushed design software to its limits. While most platforms include specialized tools for bridges, buildings, or retaining walls, very few provide a comprehensive solution for tunnels.

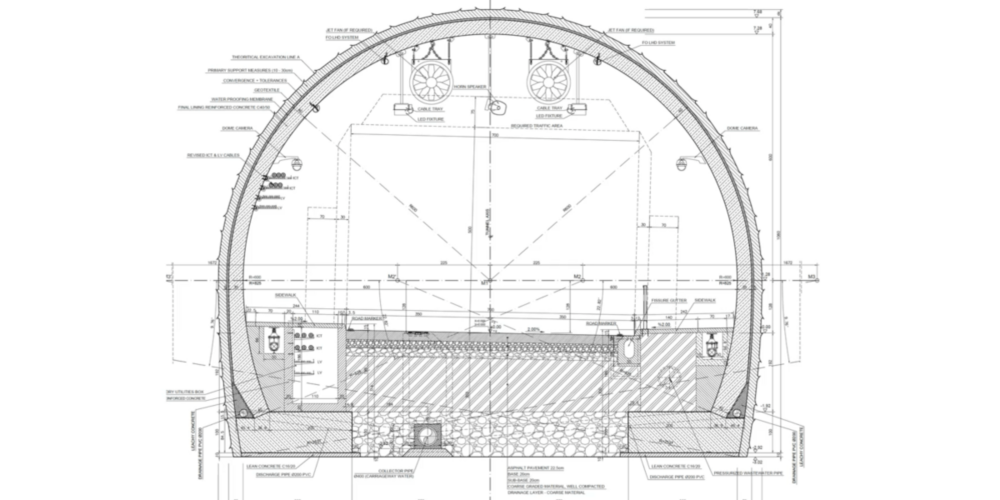

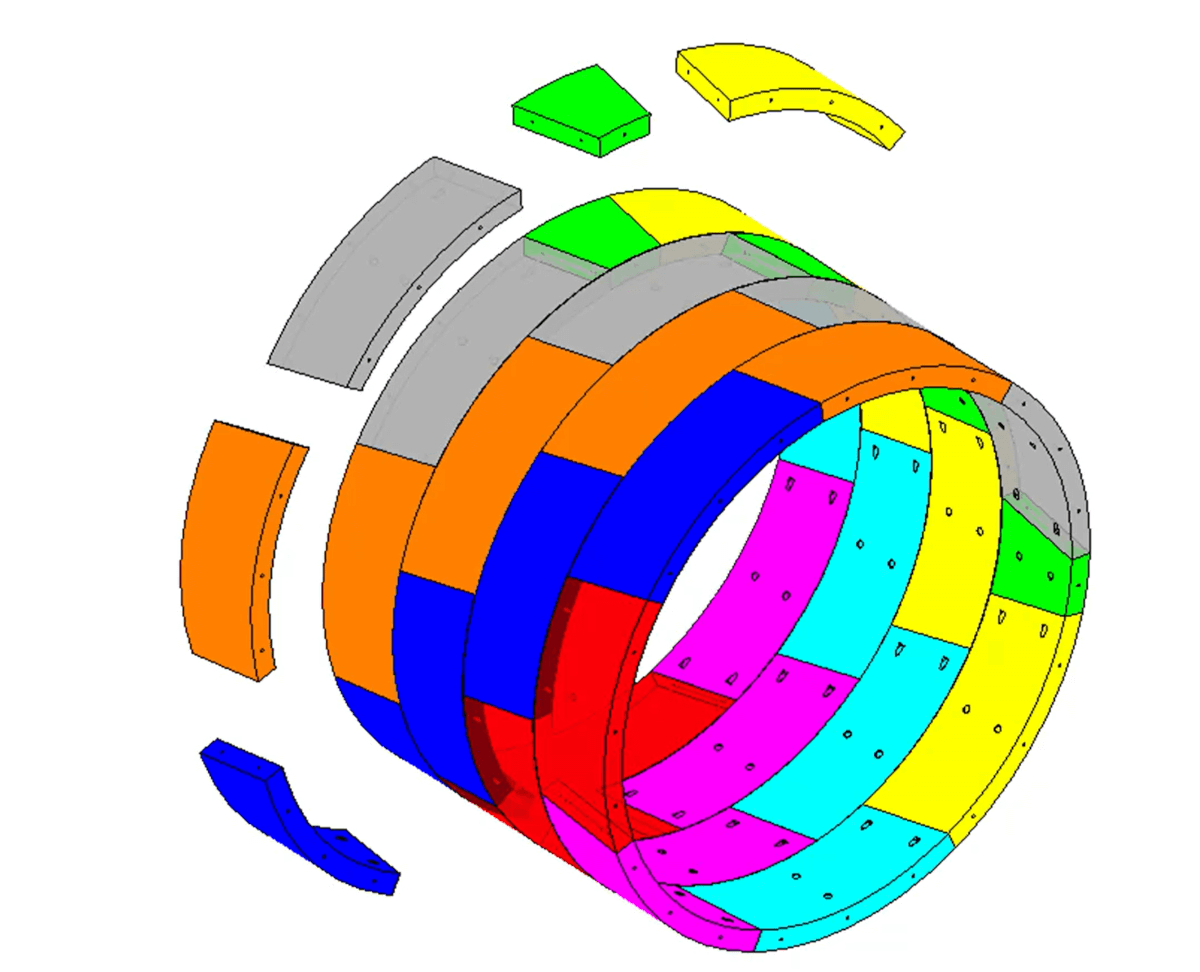

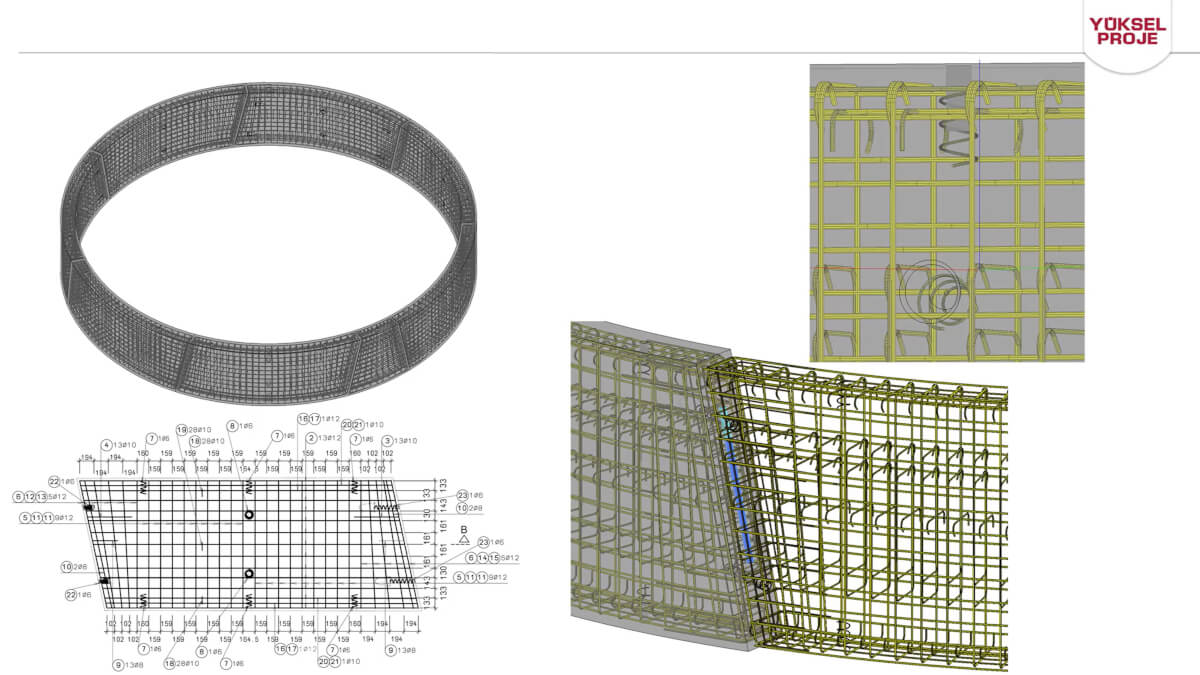

For example, in tunnel boring machine (TBM) tunnels, each ring segment is skewed or tapered to follow alignment curvature, meaning every segment differs slightly in geometry and reinforcement layout. Manually recalculating and redrawing these variations introduces errors and delays. Similarly, new Austrian tunneling method (NATM) tunnels contain a dense network of reinforcement and excavation data, creating performance bottlenecks in conventional design environments.

As a result, engineers were often forced to begin in 2D, then rebuild their designs in 3D purely for visualization or coordination purposes. This duplication of effort led to wasted time and inconsistencies between drawings and models. For Yüksel Proje, these challenges were more than just technical frustrations – they directly affected accuracy, productivity, and the ability to deliver fully coordinated 3D models.

A Parametric Leap Forward

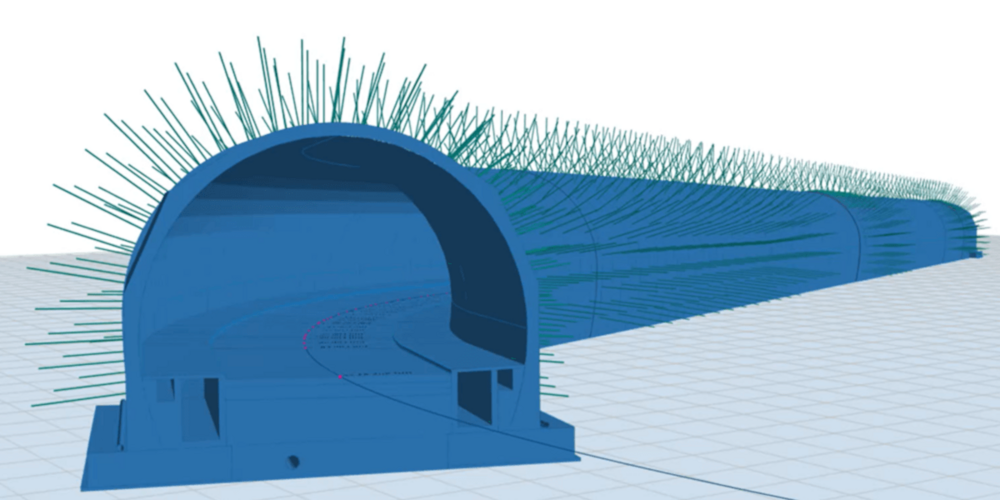

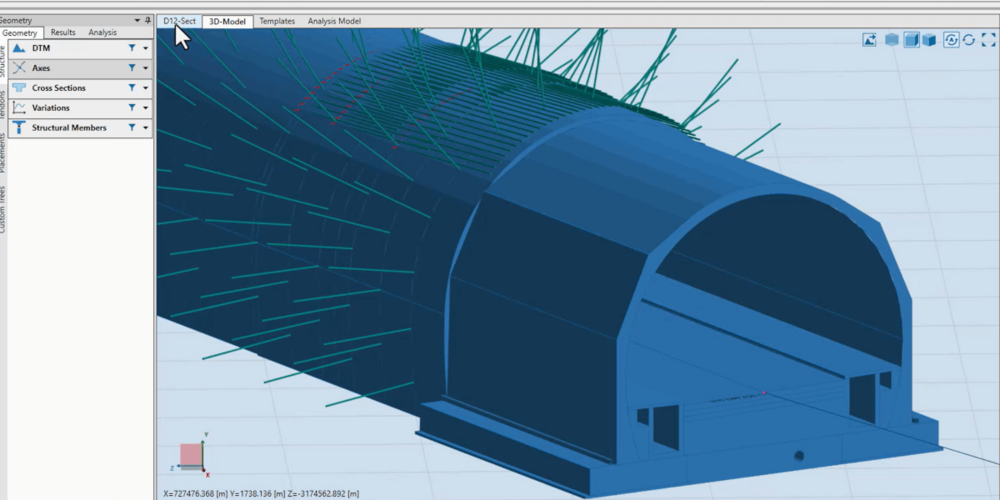

Testing the beta version of ALLPLAN Civil 2026 allowed Yüksel Proje to shift completely to a parametric 3D workflow. Using the new Tunnel Modeling – Parametric Precision feature, alignment, cross-section, and construction data were combined in one intelligent model. Changing a single variable – such as shotcrete thickness or bolt spacing – instantly updated the entire design.

Custom PythonParts developed by Yüksel Proje’s Tunnel Department automated repetitive modeling tasks. TBM ring geometries, fasteners, and reinforcement layouts were generated from just a few parameters, reducing days of manual work to minutes. The improved performance of ALLPLAN Civil 2026 also meant that even highly detailed NATM designs could be explored smoothly and interactively.

“For years, tunnel design software lagged behind other disciplines. With ALLPLAN Civil 2026, we’ve finally moved beyond 2D limitations. We can now create highly detailed 3D tunnel models parametrically – saving days of work and eliminating errors,” explains Erdem Tiryaki, Design Engineer, Tunnel Group at Yüksel Proje.

From Weeks to Minutes: Automating TBM Segment Design

TBM segment modeling showcased the full potential of this new approach. These tunnels are formed from rings of skewed concrete segments, each slightly different. Previously, every variation had to be adjusted manually. With ALLPLAN Civil 2026, Yüksel Proje encoded the geometric logic into PythonParts, enabling the software to place dowels, bolt slots, gasket channels, and reinforcement automatically according to ring geometry.

The algorithm accounts for diameter, taper, and offset, ensuring perfect alignment and structural accuracy. By embedding this logic in code, the team virtually eliminated human error and achieved a tenfold speed increase. Reinforcement quantities are now generated at full length, avoiding clashes and producing automatic detailing and reports.

“Thanks to our collaboration with the ALLPLAN development team, tunnel modeling has become faster, more flexible, and more reliable than ever before. What once took a week to model by hand can now be done in minutes,” says Raşit Emre Çakır, Tunnel Group Manager at Yüksel Proje.

Data-Driven Design for NATM Tunnels

For NATM tunnels, Yüksel Proje applied the same logic. Geological data and excavation support classes feed directly into the model, defining shotcrete thicknesses, bolt lengths, and inner lining details. When the alignment or ground conditions change, the model updates automatically.

This real-time responsiveness enables quick comparison of design alternatives and precise material optimization – crucial for safe, cost-efficient construction. Combined with ALLPLAN Civil 2026’s enhanced performance, even large and detailed models remain stable and responsive throughout the process.

A Partnership Driving Innovation

The collaboration between Yüksel Proje and ALLPLAN exemplifies how user feedback and software development can advance civil engineering practice. Working closely with the ALLPLAN team, Yüksel Proje helped refine tunnel-specific features that now benefit engineers worldwide.

Their shared vision demonstrates how experience in the field and cutting-edge technology can merge to deliver transformative results – faster workflows, higher precision, and more reliable project outcomes.

The Future of Tunnel Design

What once required weeks of manual effort can now be completed in a fraction of the time. Accuracy has improved through parametric control, performance bottlenecks have disappeared, and revisions can be handled instantly.

With ALLPLAN Civil 2026, Yüksel Proje has proven that tunnel design can be as data-driven and automated as any other branch of infrastructure engineering. Their success marks a milestone not only for their own projects but for the industry as a whole – showing how parametric design, collaboration, and innovation can redefine the future of underground construction.