Enhancing Linear Infrastructure Design: A Real-World Workflow with ALLPLAN Civil and ISTRAM

How Emch+Berger is working with ALLPLAN on one of the largest infrastructure projects in the Canton of Zug

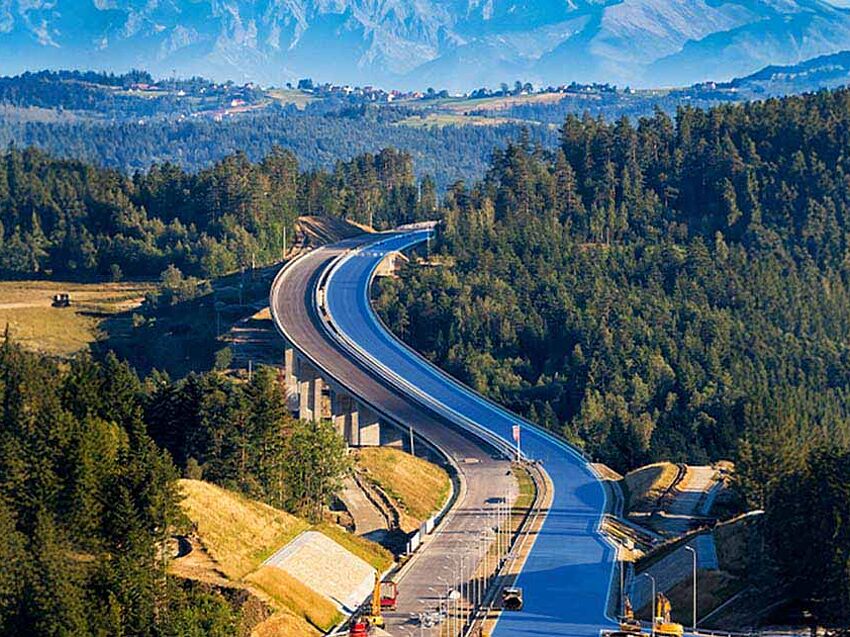

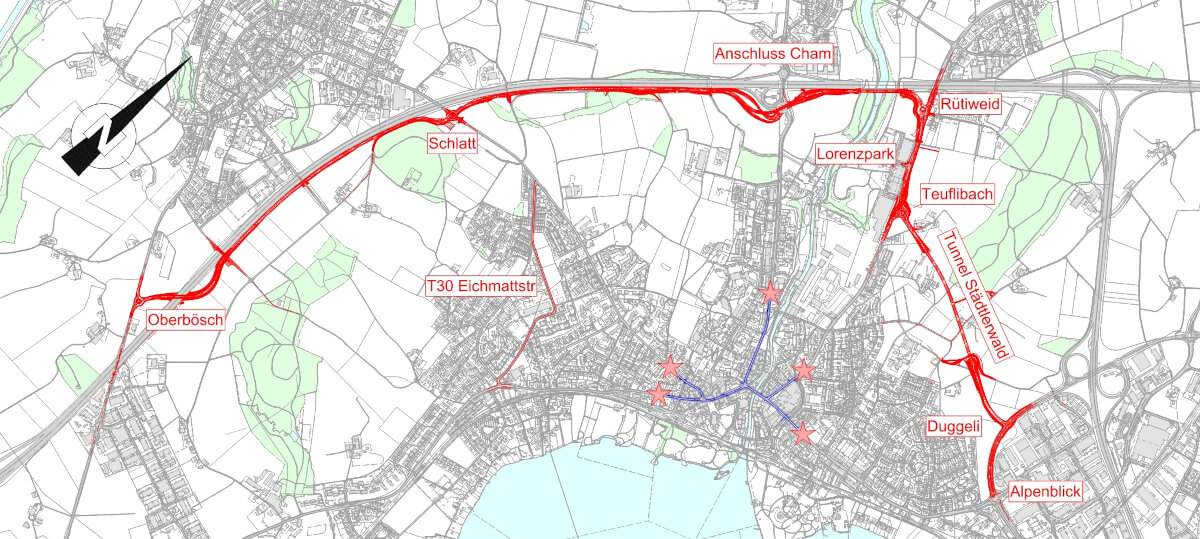

The Cham–Hünenberg Bypass (UCH) is the final major piece in the traffic concept of the Canton of Zug. The new 5.6-kilometer road connection is intended to relieve the municipalities of Cham and Hünenberg from through traffic, improve quality of life, and enhance mobility for all road users. As early as 2007, voters in the Canton of Zug approved a framework credit of 230 million Swiss francs. Construction has been underway since 2022, with commissioning planned for mid-2027.

The engineering joint venture IG UCH Cham+, led by Emch+Berger WSB AG, is responsible for planning and construction management. Two experienced experts are overseeing the project, with Manuel Sigrist, MSc ETH Civil Engineer, as Project Manager and Chief Construction Manager, and Robin Tschuppert as Lead Designer for CAD. At peak times, more than 30 employees from various engineering firms are involved simultaneously, highlighting the scale of this project.

A greenfield site with many interfaces

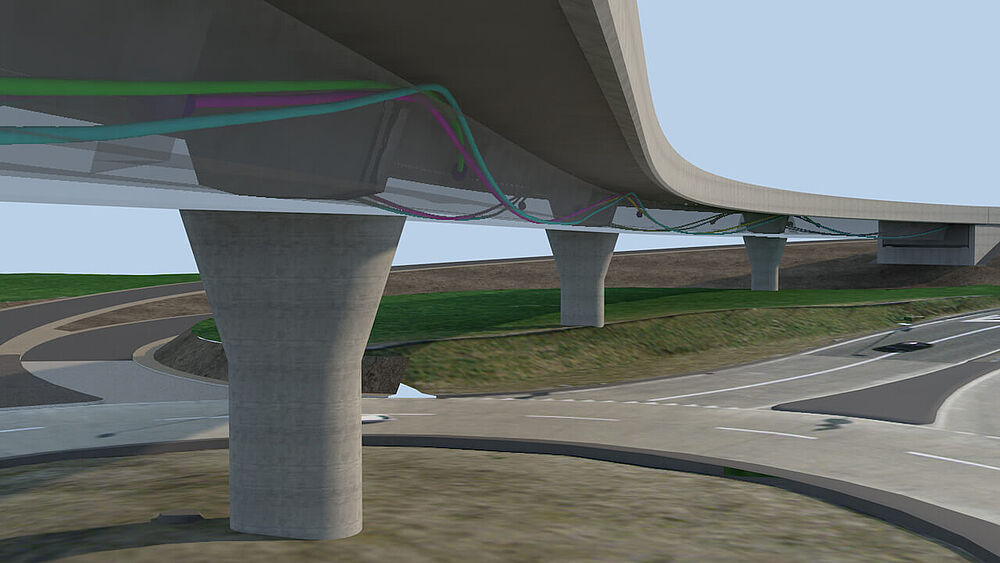

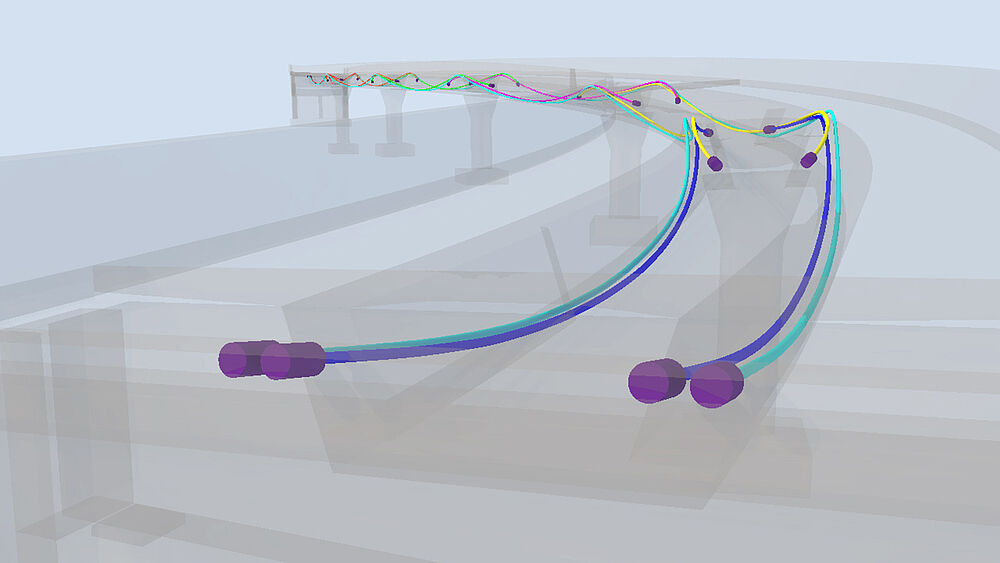

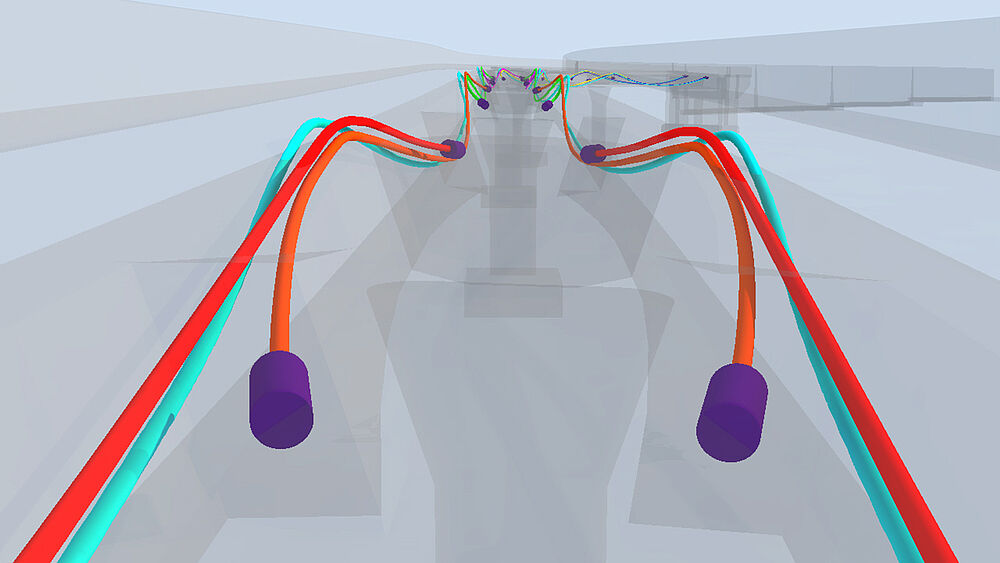

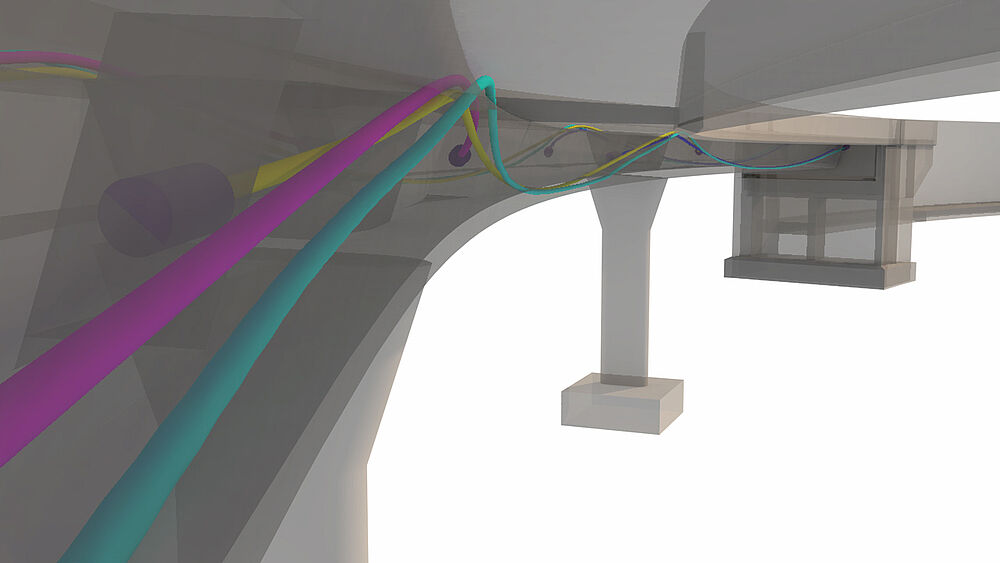

Although the project is largely being implemented on undeveloped land, planning requires numerous connections with existing roads and structures. Emch+Berger’s scope includes, among others, the design of the main road alignment with drainage pipes and cable protection systems, the 220-meter-long Gibelfeld Bridge, the Eret overpass, and a 350-meter-long pile wall.

“With ALLPLAN software, these infrastructure elements are fully modeled in 3D – as is the development of the route alignment and the creation of engineering structures and their reinforcement,” explains Manuel Sigrist. “Even though we’re working on a greenfield site, there are still many connections to the existing road network and other structures that have to be considered during the alignment design. That’s why it was important to first develop the alignment across the entire planning area, so that in a second step, the engineering structures could be inserted at the correct elevations,” says Robin Tschuppert, describing the project’s planning methodology.

Using parametrics and automation

“We built most of the supply and disposal lines parametrically – using the tools available in ALLPLAN. Where it made sense, we also used Visual Scripting to take advantage of automation,” Tschuppert adds.

For the construction execution, the companies involved still receive conventional 2D paper plans. “Additionally, we also provide our 3D models,” explains Manuel Sigrist. To ensure that everyone involved in the project is always working with the current planning status, the relevant documents are exported weekly from the CAD system. Central exchange platforms include a SharePoint environment and a CDE platform for models.

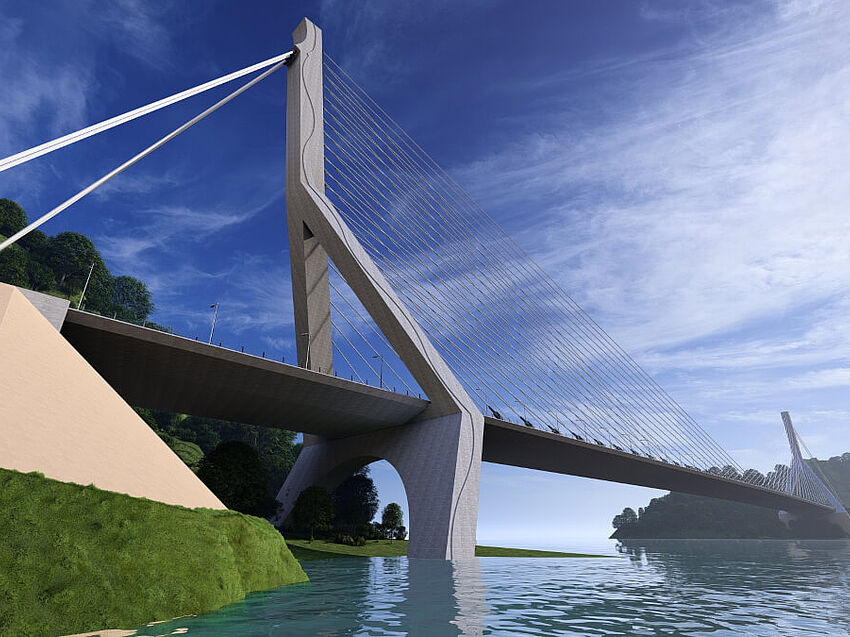

The Gibelfeld Bridge: Complex geometry without right angles

A particular highlight of this project is the Gibelfeld Bridge. It crosses the southern roundabout at the Cham motorway junction at a height of about six meters and will carry two-way traffic in the future. The bridge is designed as a hollow box structure and is particularly demanding due to its geometry.

“The S-shaped floor plan starts with a clothoid, transitions into a radius, and ends again with a clothoid. Along the longitudinal section, the highest point of the alignment is above the roundabout; meanwhile, the cross slope changes varies along the cross-section. These constraints cause torsion in the bridge body, which we were still able to develop efficiently using ALLPLAN,” explains Manuel Sigrist.

A model-based handover is also used for construction purposes: “For the formwork of the bridge and the complex formwork of the prestressing recesses, we provided the contractor with our model as an IFC file.”

Collaboration as a success factor

For an infrastructure project of this scale, close, solution-oriented collaboration between planning, construction management, and contractors is essential. Manuel Sigrist puts it succinctly: “Together, we’re working on the successful implementation of the Cham–Hünenberg Bypass megaproject – and we’re proud to say that we are fully on track.”