Reactivation of the Siemensbahn: KREBS+KIEFER relies on ALLPLAN

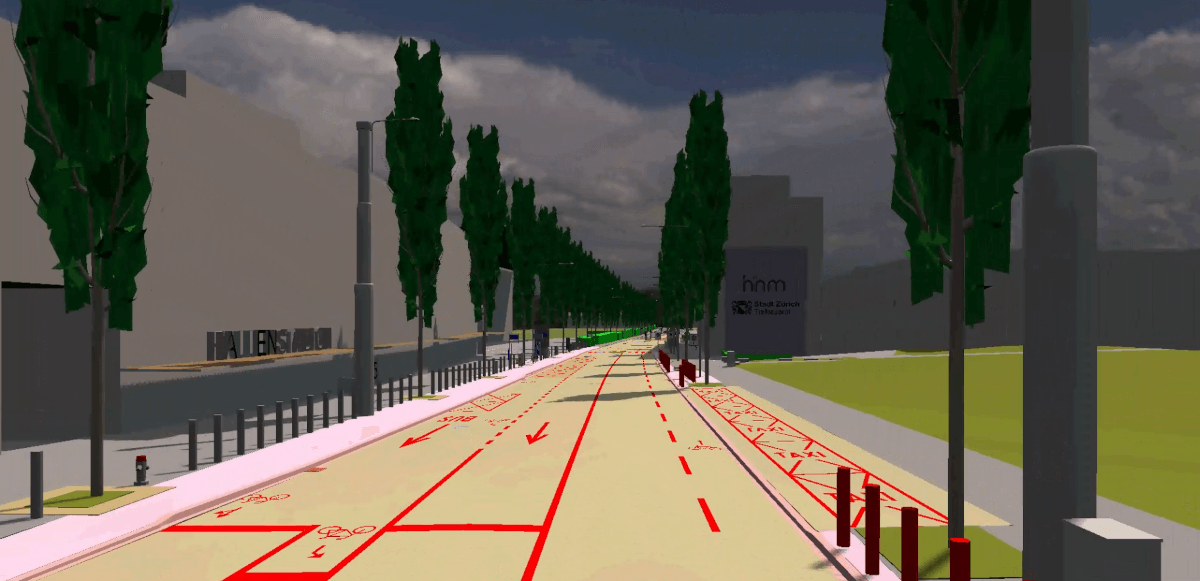

Wallisellenstrasse is the largest project in Zurich to date that has been implemented entirely with BIM. This has resulted in numerous added benefits – including for the future.

In summary: > The Wallisellenstrasse project in Zurich was delivered using a fully BIM-based workflow – from early planning through to digital construction on site. > Road construction was coordinated alongside underground infrastructure, including utilities, sewer, and drinking water systems. > Five practical BIM use cases demonstrated measurable benefits, including precise quantity takeoff, progress tracking, and model-based communication. > BIM2Field enabled machine-controlled construction and real-time access to model data on site. > 3D planning improved transparency, reduced surprises during execution, and minimized material waste. |

Even though Building Information Modeling (BIM) has been around for decades, the application of BIM methodology is still far from widespread. Despite the enormous added value, there are still digital gaps, particularly in road construction. Projects that are also implemented using "BIM2Field" are often still treated as pilot projects. The recently completed Wallisellenstrasse in Zurich is one such project. With a length of around 700 meters, it is Zurich's largest road construction and utility line project to date to be carried out entirely with BIM. Hans H. Moser AG was responsible for the planning. The office received technical support from BIMovation AG and ALLPLAN Switzerland.

Hans H. Moser AG was founded in 1976 and has a strong background in infrastructure, road, and utility line construction. Over the past ten years, the medium-sized office has undergone extensive development and expanded its service portfolio to include residential drainage, sports facility construction, and building construction. In order to position itself as a leader in BIM-based planning, the engineers work closely with Patrick Meili's BIMovation AG, which specializes in BIM modeling. This collaborative approach was also used on the Wallisellenstrasse project. In addition to the actual road, the construction project includes the renovation and new construction of underground infrastructure, including utility services as well as sewer systems and fresh water facilities.

BIM in the Wallisellenstrasse project

The consistent use of BIM in the Wallisellenstrasse project was based on various objectives. The first step was to digitally record all relevant data on the existing road in order to ensure 100% planning transparency from the outset. The project then had to be modeled in a clearly structured manner. Among other things, this was intended to enable the contractor to use machine-controlled construction methods, access digital planning data on site, and perform precise quantity calculations. The overarching goal was for all project participants to carry out the construction project on the basis of a common "language" (BIM).

The advantages of this can be illustrated by five use cases:

1. Shared data platform

2. Simple quantity calculation

3. Information management

4. Communication via the model

5. Construction progress tracking

Modeling

The modeling was carried out in ALLPLAN. In addition to standard civil engineering tools such as ALLPLAN Road and the Terrain Manager, building construction tools such as architectural components and the Level Manager were also used. The various sub-models (project, existing structure, demolition, temporary structures, etc.) were transferred to an overall model via BIMPLUS. Depending on requirements, areas relevant to planning or execution (such as individual models or specific components) could be specifically shown or hidden via the cloud-based BIM platform, which greatly improved clarity and transparency.

Quantity determination

Consistent planning with BIM enabled those involved in the project to determine exact quantities from the model. For example, the exact dimensions of prefabricated components such as pipes could be viewed with a single click for ordering purposes. At the same time, the components were enriched with additional important information such as the gradient of the pipes or numbers and shaft types for shafts.

Information management

Some tasks are difficult to represent geometrically. In such situations, Hans H. Moser and BIMovation relied on information in the form of attributes. For example, to demolish a shaft by 1.5 meters, the relevant location in the model was marked with a 3D exclamation mark and the task to be performed was stored as text information. This provided the executing company (KIBAG) with clear instructions for action directly from the model.

Section derivations

Another added value of BIM modeling is the flexible creation of sections – both in the planning office and on the construction site. This allowed cross-sections or longitudinal profiles to be defined at any point. Precise measurements could then be taken within the section (for example, the trench depth to the top of the subgrade). It was also possible to save sections for reuse at a later date.

Construction progress tracking

BIMPLUS also enabled the engineers to track construction progress from start to finish. To this end, Patrick Meili created a structure in the Multi-Model Manager that is organized on a monthly basis. This maps the construction process in such a way that it is possible to trace which construction measures were carried out in a given month. Incidentally, this also works the other way around: the structure was always expanded by two months in advance to show what had to be built during that period.

Lasting added value through digital twins

Last but not least, rigorous BIM-based planning has resulted in a digital twin of Wallisellenstrasse that encompasses all components of the road, including existing and new utility lines. This makes it possible to determine exactly what is located "under the asphalt" at any given point for future maintenance measures or other road works. This represents enormous added value for the future.