The 20 most expensive buildings in the world: from super mosques to luxury casinos

Lighter, more durable and more sustainable construction: what advantages does carbon concrete offer compared to reinforced concrete, and what disadvantages still remain?

For over 100 years, one building material has dominated the construction industry like no other: reinforced concrete. Particularly in infrastructure construction, the material’s exceptional tensile and compressive strength has been indispensable – at least, until now. In recent years, carbon concrete has been continuously developed to offer an alternative that equals – and in many respects surpasses – the traditional concrete-steel composite. Carbon fiber concrete could play a central role in sustainable construction, both in resource-efficient new builds and in the refurbishment of existing structures. However, its widespread use is currently still limited.

Carbon concrete production process

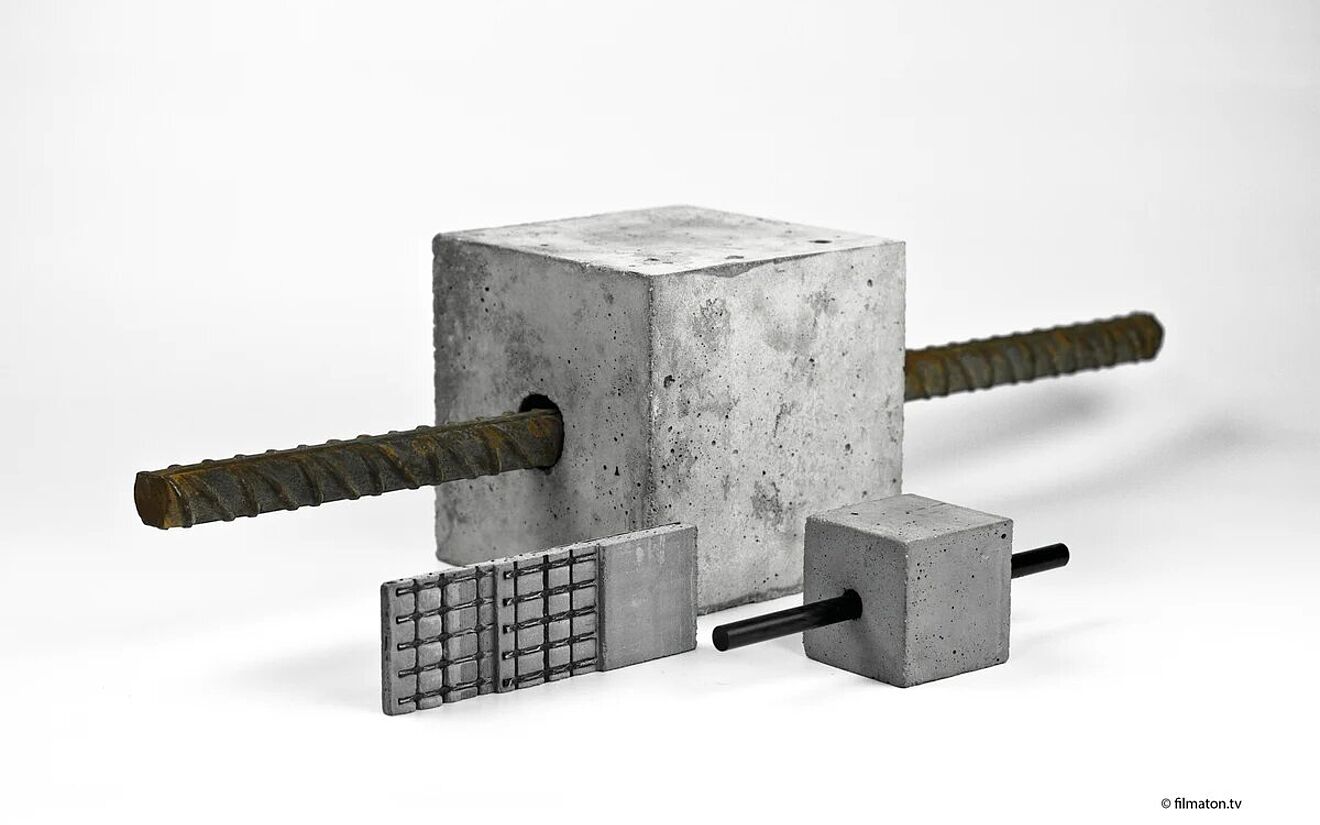

Carbon concrete is a composite material consisting of concrete and carbon fibers. It is typically produced using two different processes:

1. Casting: With casting, the concrete is poured into the formwork in one operation, while the reinforcement layers of carbon fiber mats (mesh) and rods inside are kept separate from each other using spacers.

2. Lamination: In the laminating method, concrete and reinforcement are placed alternately in layers in the formwork. A higher number of layers also increases the performance of the composite.

A third manufacturing process was developed a few years ago at the University of Augsburg. First, a carbon concrete mixture with carbon fibers averaging three millimeters in length is produced. This is then applied using a special nozzle, the shape of which determines the direction of the fibers. As carbon fibers are anisotropic – i.e. not equally strong in all directions – high-performance components can be produced by aligning all filaments along the load paths. In 2016, the researchers were able to achieve an increase in strength of 1340 percent compared to unreinforced concrete. Widespread use of the process has so far been hindered presumably by the limited use of additive processes, such as 3D printing, in the construction industry.

Innovation with a future: carbon concrete combines numerous advantages

Combining the high tensile strength of steel with the compressive strength of concrete was once an absolute game changer for the construction industry. Carbon concrete could significantly change the "game" once again, as carbon fibers weigh only a quarter of conventional reinforcing steel and are five to six times stronger. This means that the reinforcement can be reduced enormously, which in turn makes the components lighter and requires less energy for transportation. The higher load-bearing capacity also enables a slimmer design with greater design freedom.

At the same time, unlike steel, carbon fibers do not rust, which is why components made of carbon fiber concrete do not require surface protection (i.e. no extra layer of concrete). This makes it possible to build with less material and therefore with fewer resources. At the same time, the service life of carbon fiber concrete is significantly longer, as there is no rust damage to the reinforcement and the service loads are lower. According to estimates, carbon concrete structures can therefore easily last 200 years or more, whereas reinforced concrete has to be replaced after 80 years at the latest.

Using less concrete also reduces the considerable CO2 emissions associated with cement production. The latter is currently responsible for around eight percent of total global carbon dioxide emissions per year. At the same time, carbon concrete construction reduces the consumption of dwindling building sand worldwide.

Challenges and limitations: Disadvantages of carbon concrete?

Carbon concrete therefore has a number of advantages over reinforced concrete and clearly enables more sustainable construction overall. However, the widespread adoption of this composite material is currently still held back by very high costs. For example, one kilogram of carbon fiber currently costs around 16 times as much as one kilogram of reinforced concrete. However, it is also 24 times more efficient. Enormous material savings, lower transport costs, and a much longer service life with lower maintenance costs make carbon concrete more than competitive in terms of price.

Nevertheless, the cost-intensive production of carbon fiber is still the biggest obstacle to its widespread use. However, with a growing market share and an expansion of production, manufacturing costs are also likely to fall in the future. The German Institutes of Textile and Fiber Research have also developed a possible material technology solution to reduce the cost of producing carbon fibers. Using lignin (which is a waste product from paper production, for example) instead of polyacrylonitrile (PAN) as a starting material could not only reduce energy costs by 50 percent but also prevent toxic by-products. Automated production of tailor-made reinforcement, which is already being used at the HTWK Leipzig’s carbon concrete technology center, offers further potential savings.

The only real disadvantage of carbon reinforcement is its recyclability. While steel can be melted down and fully recycled, this is not always possible with carbon fibers. It is true that these can also be almost completely recycled into new filaments (up to 97 percent recovered), which can then be reused as reinforcement in carbon concrete or in other areas, such as vehicle construction. However, if the fibers fall below a certain length, thermal recycling is currently the only option.

Carbon concrete in practice: real-world applications

Carbon concrete is suitable for both new construction – particularly for structures exposed to the elements, such as bridges – and for renovation projects. In new construction projects, it enables lightweight, slender, material-efficient construction with excellent design freedom. The best example of this is the "CUBE", the world’s first carbon concrete house. The building emerged as a prototype from a research project by the "C3- CARBON CONCRETE COMPOSITE" consortium and features, among other things, a spectacular wave-shaped outer wall that tapers to an exceptionally sharp edge. Thanks to the extra-thin walls, the experimental building gains a whole twelve percent more usable space compared to a reinforced concrete construction while cutting CO2 emissions by around 70 percent.

In building renovation, the impact of carbon concrete on sustainable construction is likely to be even greater. Even the thinnest layers of carbon fiber concrete can restore ailing structures. Numerous bridges have already been renovated using this type of "minimally invasive" intervention, including three highway bridges over the Nidda. However, infrastructure construction is by no means the only area of application for existing structures. The advantages of composites also come into play in the renovation of buildings. For example, the dilapidated staircase in the Deutsches Museum in Munich was recently restored by a simple 20-millimeter-thick layer of carbon concrete.

Research and development in the field of carbon concrete

The pioneering developments in the field of carbon concrete in Germany are largely due to the aforementioned "C3 - CARBON CONCRETE COMPOSITE" consortium and their large-scale research project. This now comprises almost 100 members; 77 percent of whom come from industry, 17 percent from science, and six percent from associations and societies. The research sector includes the aforementioned German Institutes for Textile and Fiber Research, the University of Augsburg, the HTWK Leipzig, and the TU Dresden, which was responsible for building the CUBE. The main aim of the alliance is to achieve widespread use of this innovative building material. C3 strives to overcome obstacles to this widespread use "on a technical and scientific basis". To this end, the association’s work focuses primarily on information, knowledge, and technology transfer and the international expansion of its activities.

Standards for carbon concrete in sight

There are currently only around 100 construction projects in Germany in which carbon concrete is used. The reason for this still low number is the lack of standards, which means that every carbon concrete project requires case-by-case approval. For this reason, the RUBIN alliance (Regional Entrepreneurial Alliances for Innovation), funded by the Federal Ministry of Education and Research, has been working on an Industry Standard for Carbon Concrete (ISC) since 2022. This should soon serve as a guideline for all future projects involving the innovative building material and ensure standardized processes from planning, to tendering, and implementation. The great leap from research to practice is therefore perhaps just one ISC away.