The 20 most expensive buildings in the world: from super mosques to luxury casinos

Three prime examples of sustainable construction are being created at Macherei Berlin-Kreuzberg. One of them – an innovative timber-concrete hybrid building – was designed using ALLPLAN.

On the site of the former Berlin-West postal check office, a visionary new district is being built in the heart of the German capital: Macherei Berlin-Kreuzberg, scheduled for completion in 2026. In addition to six residential buildings developed by the Berlin housing association degewo, providing a total of 337 apartments, the project also features three forward-looking buildings by Art Invest Real Estate (ZECH Group). Together, these buildings aim to shape a vision of better living and working: a timber-concrete hybrid building with a new work environment (M40), a 90-meter-high, ecologically revitalized existing tower (M50), and a climate-neutral office building (M60). Each of these highly diverse buildings pursues its own innovative approach to sustainable construction and healthy urban development. The first of these was planned primarily with ALLPLAN.

A wooden square for new work

Following existing Macherei projects in Offenbach and Munich, the one in Berlin-Kreuzberg is now the third of its kind. The three landmark buildings of this large-scale development at Hallesches Ufer 40-60 are each being designed by a renowned architectural firm. M40 was designed by KEC Architekten (also part of the ZECH Group) from Berlin. Their design envisages an eight-story office and commercial building, which is also known as Holzcarré (Timber Square) due to its shape and choice of materials. Covering almost 28,000 square meters, it will house offices and conference rooms as well as space for events, restaurants, and commercial use. All upper floors can be flexibly configured in terms of their room layout and can be connected to form up to four units. A landscaped courtyard, together with lush green roof areas, absorbs rainwater and contributes to a healthier local microclimate.

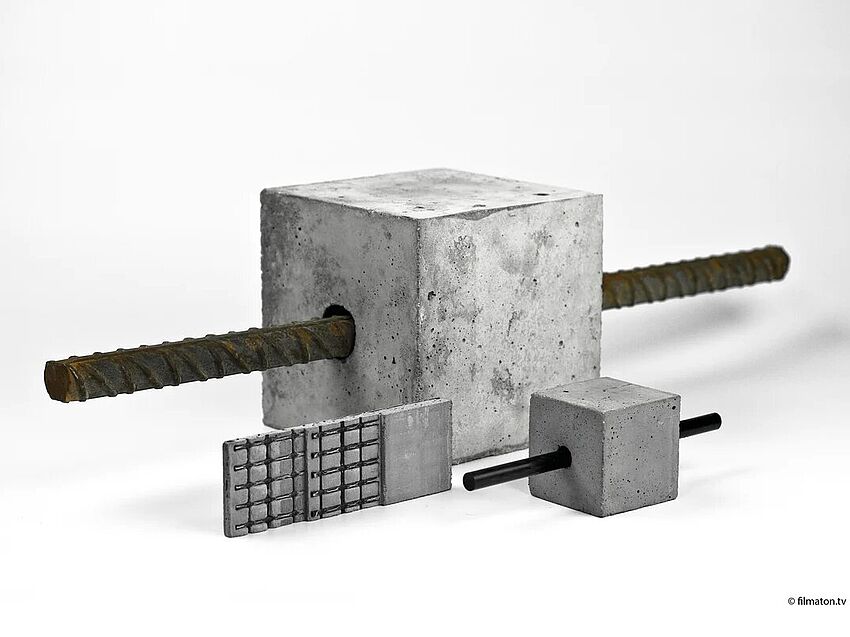

Innovative construction based on the CREE system

A particular highlight of the new building is its construction, which follows the innovative CREE system. Prefabricated timber-concrete ribbed ceiling elements are supported by paired glulam columns. For larger floor spans, such as those found in M40, additional steel beams are incorporated (a timber-concrete composite alternative is also possible here, but results in larger cross-sections). In this system, non-load-bearing façade elements made of timber are usually suspended in front of the supporting structure. In the case of M40, however, these are being replaced for the first time by a curtain wall façade made of glass elements. The ground floor, which serves as a base, is constructed of reinforced concrete and has a curtain wall façade made of architectural concrete panels with a washed finish.

Detailed planning for over 2,400 prefabricated parts with ALLPLAN

The complex planning for the prefabricated parts was carried out by Planungsbüro Bade (PB) from Isernhagen, which, like the client and the responsible architectural firm, also belongs to the ZECH Group. This involved planning all prefabricated components, from reinforced concrete columns and beams to CREE composite elements (ceilings and glulam columns), as well as the precast concrete elements for the ground floor façade. A total of 2,439 precast elements from 329 different components had to be planned – plus over 115,000 installation parts, such as screws. PB used ALLPLAN for this, with the engineers benefiting from the fact that KEC Architekten had already created their building design with the same software. This ensured time savings when setting up the project or incorporating design changes, among other things.

Additional advantages came from ALLPLAN’s filter functions – which was particularly valuable given the large number and wide variety of component types – as well as its visualization tools, which helped to provide a quick overview. PB modeled the CREE ceilings as free-form bodies. The glulam beams and “mirrors” (concrete panels) were modeled independently of one another, enabling the creation of shop drawings for the prefabrication of the timber components, as well as accurate quantity take-offs, without additional steps. For collision checks between built-in components and reinforcement, PB also modeled the reinforcement for highly reinforced components such as floor slabs and access cores in ALLPLAN with minimal extra effort.

Sustainability: climate protection, biodiversity, and circular construction

The Macherei Berlin-Kreuzberg is designed with a strong focus on sustainability. M40 is aiming for DGNB and LEED Gold, as well as WELL certifications. Thanks to the use of approximately 2,000 cubic meters of spruce wood, the building saves around 2,000 tons of CO2. In addition to climate protection, the ambitious project also focuses on biodiversity, which it promotes with lush green spaces and additional nesting boxes and bee hotels.

Another key feature is the use of BIM-based planning for all three buildings, each of which will generate a digital twin. These will serve as the basis for circular construction, among other things. To this end, the BIM models are uploaded to the madaster digital material register and the material information contained therein is stored in a material passport. This means that at the end of their life cycle, the three buildings and their built-in materials will be available as a transparent raw material store for future construction projects.