What is Tim?

Successful precast design needs perfect work preparation, quality-assured data for production, commercial systems, and BIM applications, as well as seamless information flows.

- From complete operations scheduling to assembly on the construction site.

- Tim supports you in planning production, stacking, and assembly as well as quality assured data creation.

HOW TIM BENEFITS YOUR BUSINESS

Features of Tim

Skip

- 1 \ WORK PREPARATION Perfect Overview

- Digitization

- Clear Visualization

- Seamless Collaboration

- Individual Requirements

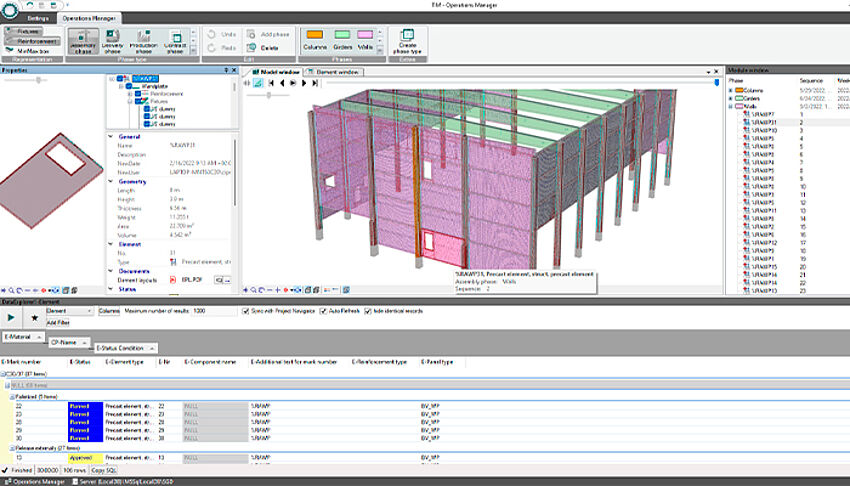

The 3D views in Tim ensure absolute clarity and comprehensibility when stacking and creating the production and assembly sequence.

[...read more]The 3D views in Tim ensure absolute clarity and comprehensibility when stacking and creating the production and assembly sequence.

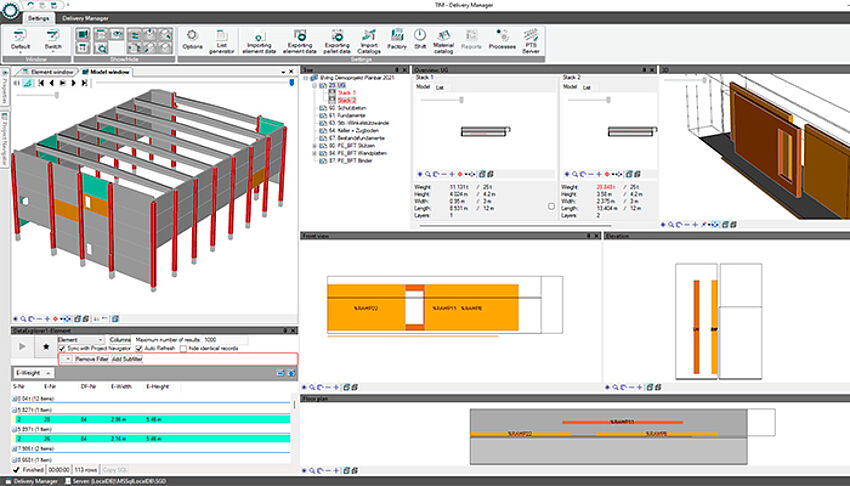

Tim replaces analog production folders with digital and automated information flows.

[...read more]Tim replaces analog production folders with digital and automated information flows.

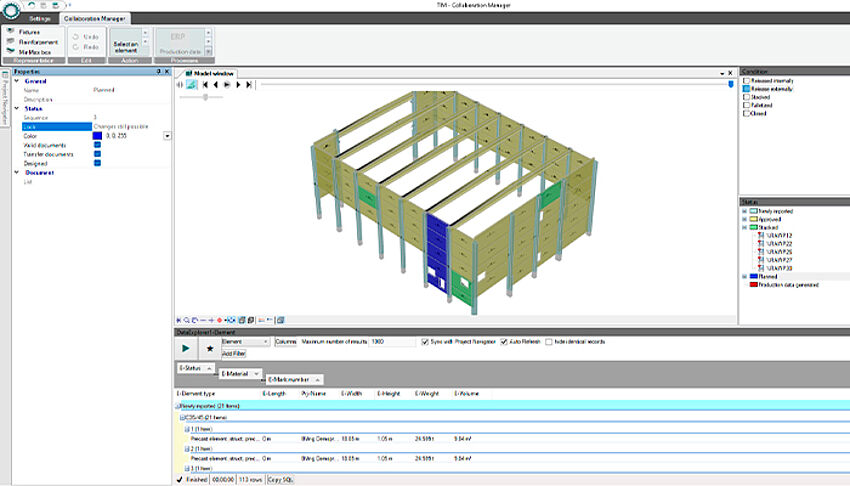

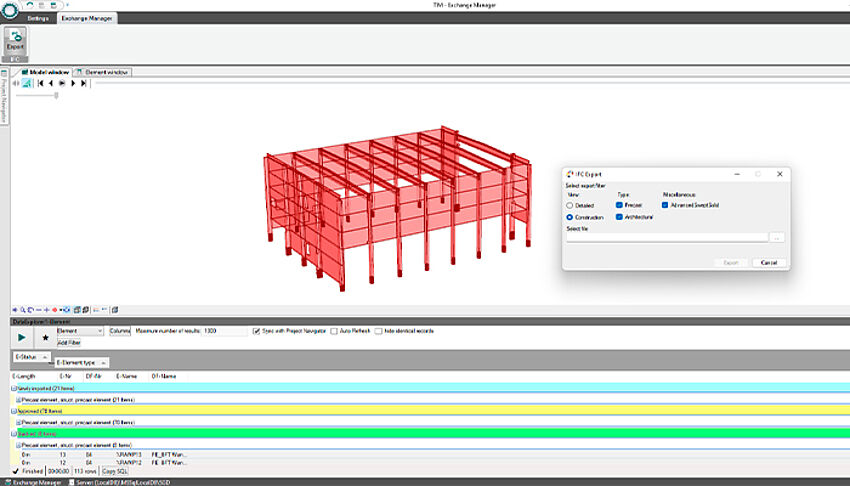

Color-coded marks in the 3D model indicate the current status of each precast element.

[...read more]Color-coded marks in the 3D model indicate the current status of each precast element.

Tim enables fast and easy generation of IFC data.

[...read more]Tim enables fast and easy generation of IFC data.

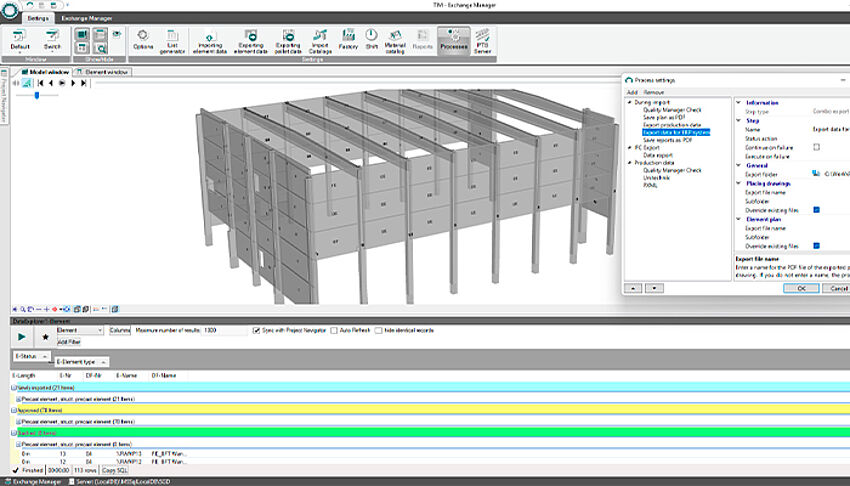

Define for yourself which process steps should be automated and when. This way, nothing can be omitted, and your teams gain valuable time.

[...read more]Define for yourself which process steps should be automated and when. This way, nothing can be omitted, and your teams gain valuable time.

Choose Workflow phase

Explore ALLPLAN Solutions

WELL-KNOWN COMPANIES WHO TRUST ALLPLAN:

Our Offering