ALLPLAN precast

the ultimate Software

for Precast slabs design

Automated workflows for the design of precast slabs save time and resources while increasing quality and efficiency.

Buy ALLPLAN Precast

ALLPLAN Precast

Please make your selection

Your selection

3 years

1 user

22.257,00 EUR

excl. VAT

Your selection

1 year

1 user

7.419,00 EUR

excl. VAT

Your selection

1 month

1 user

927,00 EUR

excl. VAT

- directDebit S€PA

What is the best software for designing precast slabs?

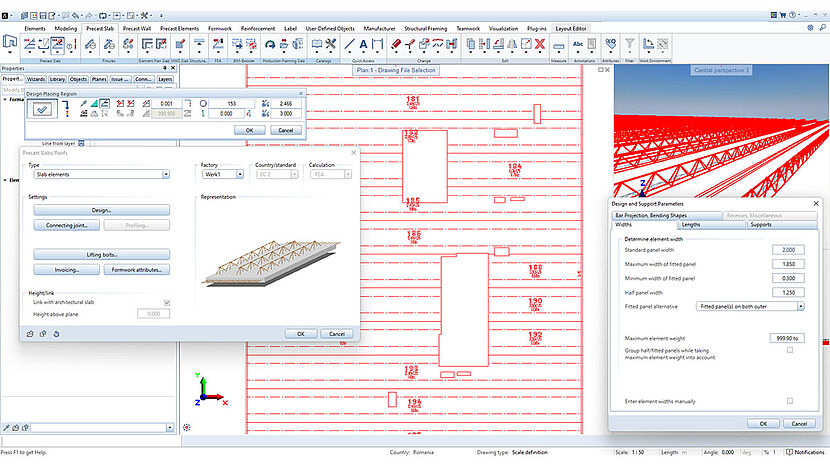

Precast slabs include element slabs, solid slabs, hollow core slabs, and brick slabs. With automated planning tools in ALLPLAN Precast, the slabs are intelligently divided into producible and deliverable slab elements based on the individual production systems. The solution also automatically generates reinforcement data tailored to the specific production options. For example, ALLPLAN Precast Premium automatically places the composite recesses in the precast floor slabs and takes care of sleeves and transport anchors. For precast floor slabs, ALLPLAN performs a shear force and bond check and, if necessary, installs the required lattice girders.

In addition, ALLPLAN generates automated shop drawings, including reinforcement, fixtures, and dimensions, and updates them continuously. This means that the plan and model are always up to date.

allplan Precast Benefits at a glance

Success Stories

CUSTOMER PROJECTS DESIGNED AND BUILT WITH ALLPLAN

Our Offering