Prefabrication

FOR PRECAST DESIGNERS WHO DEMAND MORE

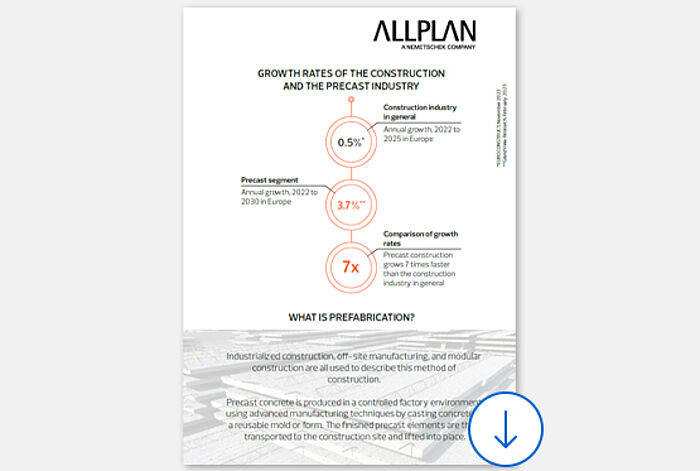

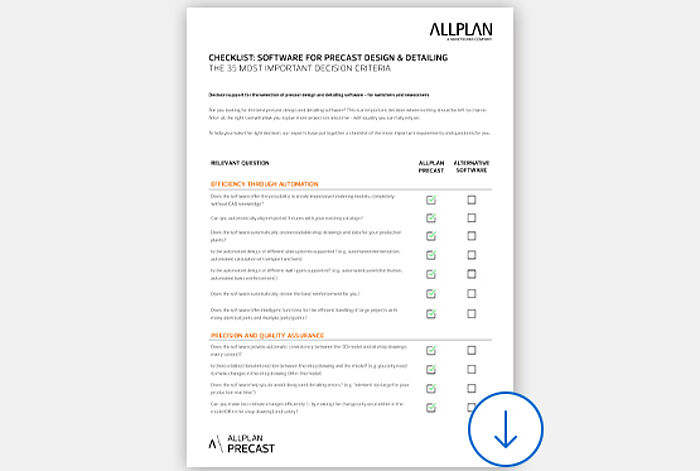

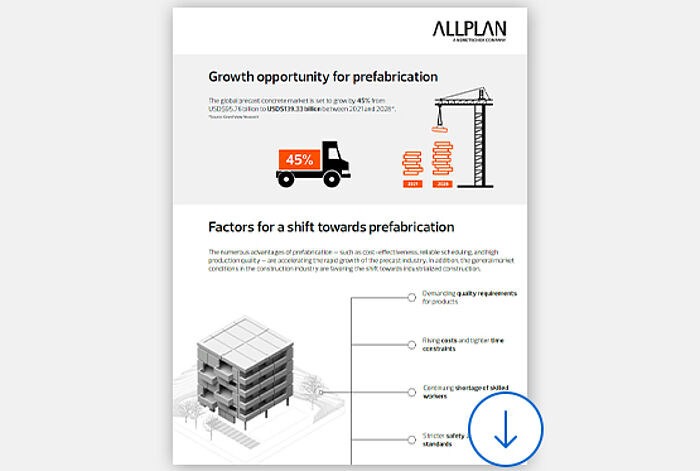

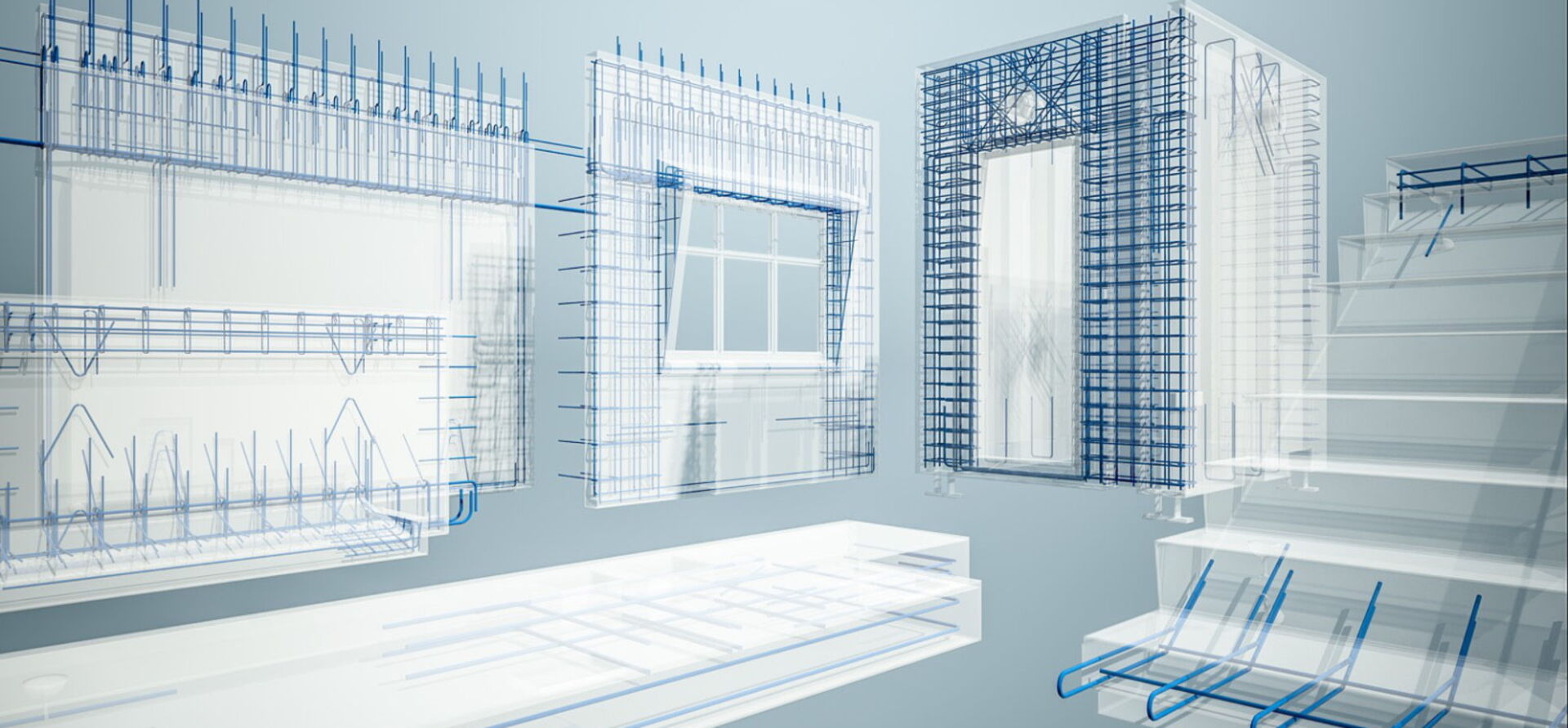

Precast is one of the fastest growing segments of the construction industry. That's why ALLPLAN offers unique workflows for the design, detailing, and implementation of precast projects. Highly automated workflows enable maximum productivity and precision. Learn more about the integrated precast functions in ALLPLAN!

ALLPLAN – BIM SOLUTIONS FOR PREFABRICATION

What characterizes successful precast projects is the perfect mix of extensive knowledge, the commitment to absolute precision, and the right tools.

ALLPLAN supports you in all project phases: from the impressive 3D quotation model and 3D precast model to complete sequence and production planning, as well as clear 3D stacking and seamless billing data.

9 REASONS TO CHOOSE ALLPLAN

Our Offering

Bim Software

for the AEC Industry

ALLPLAN offers unique workflows for the design and implementation of precast projects. Highly automated workflows enable maximum productivity and precision. Discover the integrated precast functions in ALLPLAN.