ALLPLAN Precast

the ultimate Software

for Precast Walls design

Automated workflows for the design of precast walls save time and resources while increasing quality and efficiency.

Buy ALLPLAN Precast

ALLPLAN Precast

Please make your selection

Your selection

3 years

1 user

22.257,00 EUR

excl. VAT

Your selection

1 year

1 user

7.419,00 EUR

excl. VAT

Your selection

1 month

1 user

927,00 EUR

excl. VAT

- directDebit S€PA

What is the best software for designing precast walls?

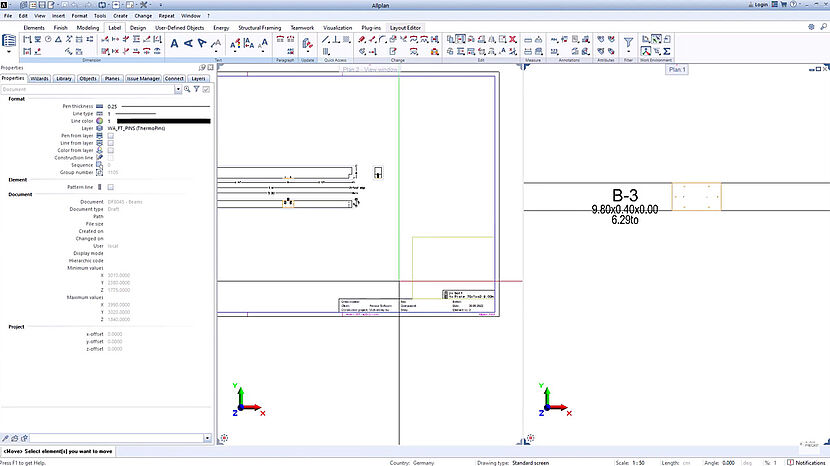

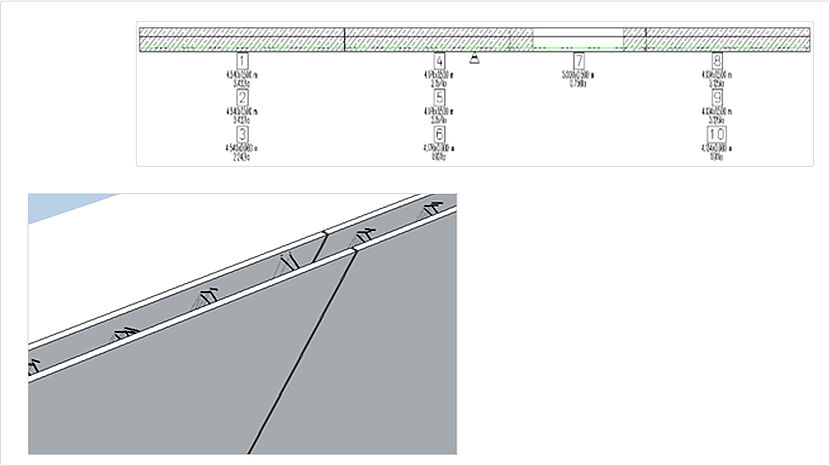

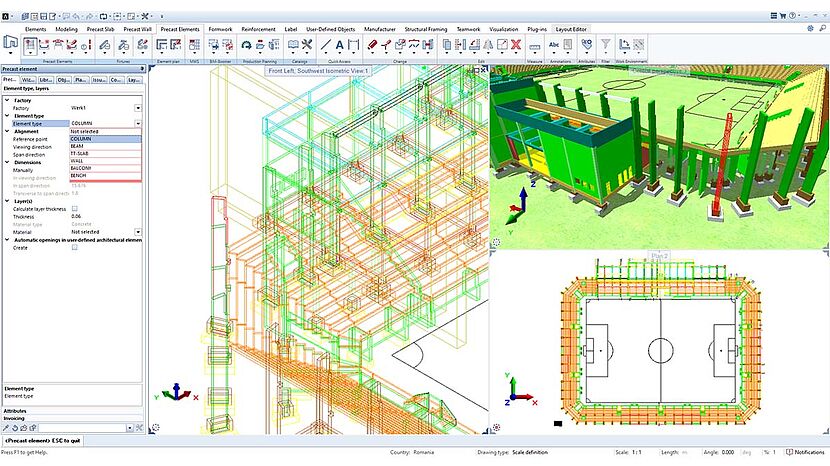

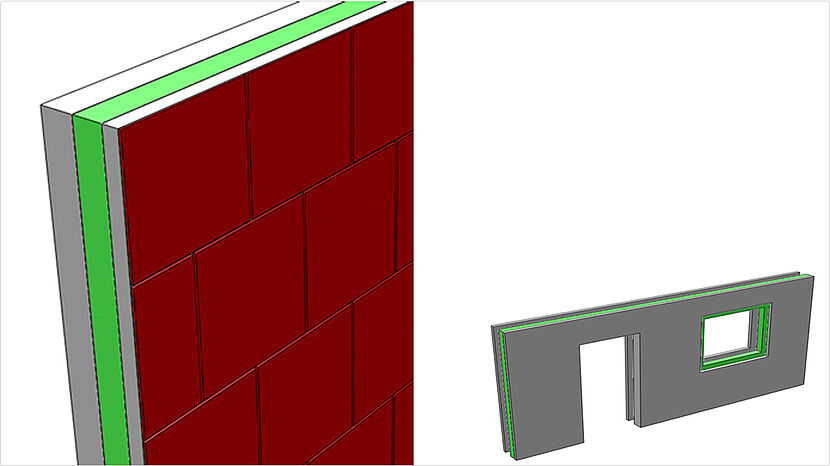

Precast walls include solid walls, double walls, sandwich walls, thermal walls, and brick walls. With the automated planning offered by ALLPLAN Precast, 3D components, architectural objects, and PythonParts can be converted into intelligent precast elements with just a few clicks. The software establishes relationships between the precast element and components such as formwork, reinforcement, and fixtures, allowing changes to be made quickly and reliably. In addition, ALLPLAN takes care of the elementization; i.e. the intelligent division into wall elements that can be produced and delivered by the individual production facilities. The software also takes into account the load capacity of the construction site crane. This 3D crane is also available as a PythonPart in the library.

allplan Precast Benefits at a glance

Success Stories

CUSTOMER PROJECTS DESIGNED AND BUILT WITH ALLPLAN

Our Offering