How the latest releases from Allplan Precast maximize productivity in the booming prefabrication industry

ALLPLAN, global provider of BIM solutions for the AEC industry, today announced the global rollout of its new BIM software for prefabrication. Planbar and Tim 2022 provide an integrated working method for engineering offices, precast plants and internal design departments, from the initial design to the successful implementation on the construction site.

Software is a game changer when it comes to increasing efficiency in precast projects. The right software helps companies to exploit the advantages of automation and digitalization by accelerating processes. Allplan Precast, ALLPLAN's competence center for prefabrication, has refined its software solutions specifically for precast construction through the continuous development of proven functionalities and by adding new workflows with additional productivity benefits. The new versions offer further product quality improvements for shop drawings, additional functionalities for the modelling of precast walls, improved data management as well as an optimized user experience. Our Customer Excellence Services enable you to get the most out of your software through customized training, individual consulting, and responsive support.

Prefabrication as role model for digitization and automization

Kevin Lea, Senior Vice President of Product Management at ALLPLAN, sees strong growth for prefabrication. “Precast manufacturing is a key strategic pillar of ALLPLAN and we will continue to drive development of our precast products, including Planbar and Tim, to further support this section of the industry,” he emphasizes. According to forecasts by Grand View Research, prefabrication is expected to grow by up to 65% faster than the rest of the construction industry. The rapid growth can be explained by the numerous advantages of prefabricated construction: reliable time and cost planning, highest precision of the prefabricated elements, increased safety on the construction site, shorter erection time and thus lower impact on the local population due to reduced noise, dust and construction site traffic.

The latest versions of Planbar and Tim offer new and further developed functions in the design and implementation of precast projects. The Allplan Precast solutions optimally support precast concrete plants and design offices in all project phases, from the impressive 3D tendering model and the high-precision 3D precast model to complete sequencing and production planning, as well as clear 3D stacking and seamless billing data.

Smart solutions for precast construction by ALLPLAN

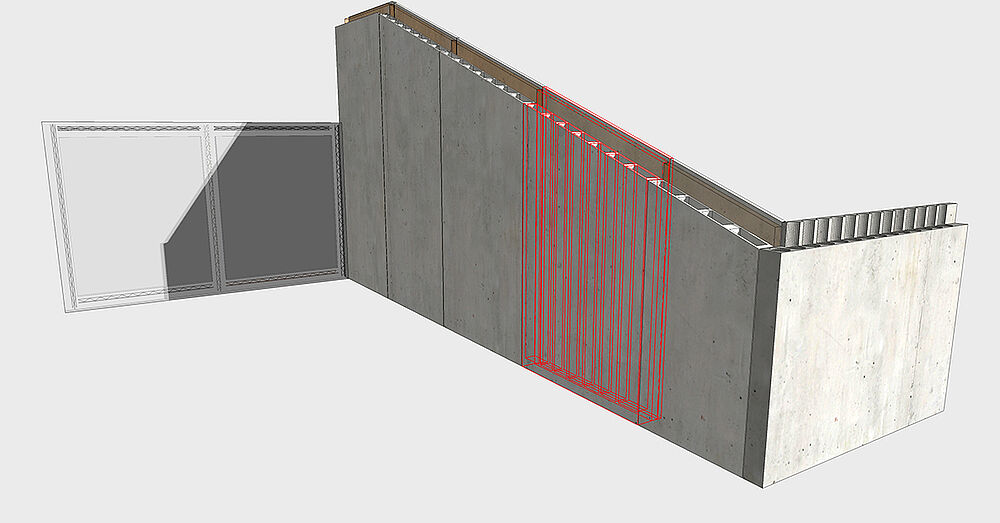

Planbar is considered one of the world's leading BIM solutions for the design and detailing of precast concrete elements. It is easy to learn, with automated workflows such as one-click reinforcement or quick importing of architectural models and fixtures, as well as smart functions for highly efficient and safe workflows. Thanks to the unique Elementplan-Technology, the shop drawings already contain the exact reinforcement, fixtures, and dimensions. In addition, all shop drawings are 100% consistent with the model at all times, which massively reduces the risk of errors and eliminates numerous manual work steps.

Tim offers vivid work preparation in 3D, direct access to all relevant project information, and sophisticated quality assurance. In addition, Tim enables automated information flows and thus perfect interaction between ERP, CAD, MES, and other BIM applications.

With the merger of the previously independent Nemetschek brand PRECAST SOFTWARE ENGINEERING, into ALLPLAN, the 2022 releases are all about even more synergies between Allplan, Planbar, Tim, and the collaboration platform Bimplus. An illustrative example of this seamless collaboration is the engineering firm Mossel in the Netherlands. The design office relies on both Allplan and Planbar in its daily work. Mossel uses Planbar for the efficient and error-free modeling of precast walls, precast slabs, and structural precast elements. The owner, Benjamin Mossel, is enthusiastic about the user experience. “Everything I learn in Planbar also helps me in Allplan, and vice versa. This is because Planbar uses Allplan as its technical basis, which means that the two solutions offer the same user interface. For engineering offices that design precast elements, there is only one product, and that is Planbar,” he explains.

What specific added features can we expect from the releases on October 28th, 2021?

Customers who already use Planbar and Tim will once again be delighted with the once again noticeably improved efficiency benefits, even more openBIM workflows for seamless collaboration, and further advanced automation options. An overview of the 2022 release highlights include:

NEW IN PLANBAR 2022

- Further simplification of BIM processes regarding data export and Bimplus upload

- Numerous improvements in shop drawings, including associative dimensioning

- Two additional iWall modules for brick and hollow core walls

- New IFC export function for precast elements

- Additional Dextra libraries for even more efficient handling of these fixtures

NEW IN TIM 2022

- Tim Essentials brings the most popular Tim features at an attractive entry-level price – including time-saving process technology

- Numerous other developments such as improved CSV export, extended rule checks, and easier project management

- Expandable at any time with additional modules such as stacking, pallet assignment, and much more